Improve Your Prototyping Process with CNC Parts

By:Admin

Founded in 1998, {} has quickly established itself as a top player in the field of CNC manufacturing. The company's commitment to quality and innovation has earned them a solid reputation among clients both in the domestic and international markets. Specializing in the production of CNC machined parts, {} has the capabilities to handle complex projects with tight tolerances, ensuring that their clients receive products that meet their exact specifications.

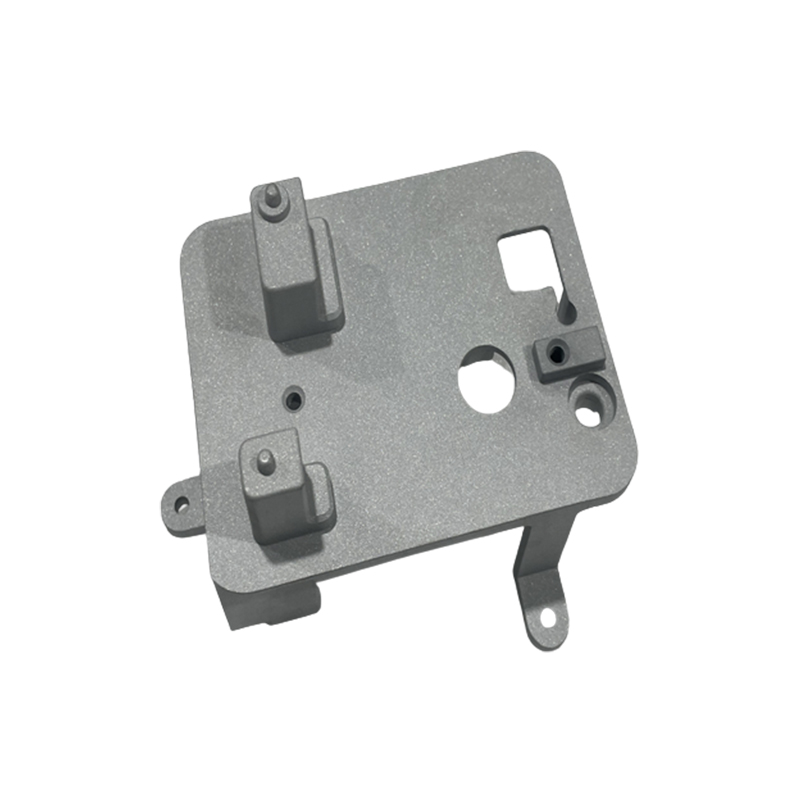

One of the key services offered by {} is prototyping CNC parts. This process involves creating a preliminary version of a part or product using computer-aided design (CAD) software and then machining it out of a solid material using a CNC machine. This allows engineers to test the design for fit, form, and function, making any necessary adjustments before moving to full-scale production. With their advanced CNC machining capabilities, {} is able to produce prototypes quickly and accurately, helping their clients to bring their products to market faster.

In addition to prototyping, {} also offers a range of other CNC machining services, including milling, turning, grinding, and more. This allows them to handle a wide variety of projects, from simple components to complex assemblies. With a focus on precision and quality, {} is able to meet the needs of clients in industries such as aerospace, automotive, medical, and more.

Recently, {} has made significant investments in their prototyping capabilities, acquiring new CNC machines and software to streamline the process. This has allowed them to offer even faster turnaround times on prototypes, helping their clients to iterate and refine their designs more efficiently. By staying at the forefront of technology, {} is able to provide the highest quality prototyping services to their clients, ensuring that their products are market-ready in the shortest possible time.

One of the key advantages of working with {} is their commitment to customer satisfaction. Their team of engineers and machinists works closely with clients throughout the prototyping process, offering guidance and expertise to ensure that the final product meets their exact requirements. By taking a collaborative approach, {} is able to deliver prototypes that not only meet technical specifications but also exceed expectations in terms of quality and performance.

In conclusion, prototyping CNC parts is a crucial step in the manufacturing process, allowing companies to refine their designs and bring high-quality products to market. With their advanced technology and expertise, {} is well-positioned to meet the prototyping needs of clients in a wide range of industries. By investing in their capabilities and maintaining a strong focus on customer satisfaction, {} has solidified their position as a top provider of CNC machining services, helping to drive innovation and success for their clients.

Company News & Blog

Custom Plastic Prototype Fabrication Services: Rapid and Affordable Solutions

[Company Name] is a leading manufacturer in the field of plastic prototype fabrication. With a team of experienced professionals and cutting-edge technology, the company is dedicated to providing high-quality prototypes that meet the specific needs of their customers. [Company Name] has been at the forefront of innovation in the industry, consistently pushing the boundaries of what is possible with plastic fabrication.The company specializes in the fabrication of plastic prototypes for a wide range of industries, including automotive, aerospace, medical, and consumer goods. Their diverse portfolio of clients speaks to their versatility and ability to adapt to the unique requirements of each project. Whether it's a complex automotive component or a medical device prototype, [Company Name] has the expertise and resources to deliver exceptional results.One of the key factors that sets [Company Name] apart from its competitors is its commitment to using the latest technology and techniques in plastic prototype fabrication. The company regularly invests in state-of-the-art equipment and software to ensure that they can offer the most advanced solutions to their clients. This dedication to innovation has allowed [Company Name] to stay ahead of the curve and consistently deliver prototypes that exceed industry standards.In addition to their technical expertise, [Company Name] prides itself on its customer-centric approach to business. The team at [Company Name] understands that each project is unique and requires a tailored approach to achieve the best results. They work closely with their clients from the initial concept stage through to the final prototype, offering guidance and support every step of the way. This collaborative approach has earned [Company Name] a reputation for delivering exceptional customer service and building long-lasting relationships with their clients.One of the most significant advantages of working with [Company Name] is their quick turnaround time. The company understands that time is of the essence when it comes to prototype fabrication, and they have developed efficient processes to ensure that their clients receive their prototypes in a timely manner. This commitment to meeting deadlines has made [Company Name] a trusted partner for companies looking to bring their products to market as quickly as possible.Despite the challenges posed by the global pandemic, [Company Name] has continued to thrive and expand its capabilities. The company has implemented strict safety measures to protect its employees and customers, allowing them to maintain their high standards of production without interruption. [Company Name] is committed to staying at the forefront of the industry, and they have ambitious plans for further growth and development in the coming years.With a strong focus on quality, innovation, and customer satisfaction, [Company Name] is well-positioned to continue leading the way in plastic prototype fabrication. The company's dedication to excellence and its ability to adapt to the ever-changing needs of its clients make them a valuable partner for businesses looking to bring their ideas to life. As they look to the future, [Company Name] remains committed to pushing the boundaries of what is possible in plastic prototype fabrication, and they are excited to take on new challenges and opportunities in the years to come.

5 Innovative Prototyping Methods Shaping Manufacturing in China

Prototyping China Expands its Reach with Cutting-Edge ServicesIn today's fast-paced and ever-evolving world of technology and innovation, the importance of prototyping in product development cannot be overstated. Prototyping plays a crucial role in bringing new ideas to life and accelerating the production process, allowing companies to stay ahead of the competition. Recognizing the significance of prototyping in the manufacturing industry, Prototyping China has positioned itself as a leader in providing high-quality and efficient prototyping services.With a strong commitment to innovation and excellence, Prototyping China has expanded its reach and capabilities to meet the growing demand for advanced prototyping solutions. The company has leveraged its extensive experience and expertise to deliver cutting-edge services that cater to the diverse needs of its clients. From rapid prototyping to CNC machining, injection molding, and more, Prototyping China offers a comprehensive range of prototyping services that are tailored to each client's unique requirements.As a leading prototyping company, Prototyping China's core mission is to provide its clients with top-tier prototyping solutions that are tailored to their specific needs. The company prides itself on its ability to deliver high-precision prototypes with quick turnaround times, ensuring that clients can bring their products to market faster and more efficiently. With a focus on quality and customer satisfaction, Prototyping China has built a solid reputation for excellence in the prototyping industry.At the heart of Prototyping China's success is its state-of-the-art facility, which is equipped with the latest technology and machinery. The company's advanced prototyping capabilities enable it to produce prototypes with unparalleled precision and accuracy, setting it apart from its competitors. By investing in cutting-edge equipment and staying at the forefront of industry trends, Prototyping China remains at the forefront of the prototyping industry, consistently delivering superior results to its clients.Furthermore, Prototyping China's team of highly skilled engineers and technicians are dedicated to pushing the boundaries of prototyping and setting new standards for excellence. With their expertise and passion for innovation, the company's team ensures that each prototype meets the highest quality standards and exceeds client expectations. Whether it's a complex component or a simple prototype, Prototyping China has the capabilities and knowledge to bring any design to life with precision and efficiency.In addition to its technical prowess, Prototyping China places a strong emphasis on fostering strong and lasting relationships with its clients. The company works closely with each client to understand their unique prototyping needs and collaborate on developing solutions that align with their goals. Prototyping China's commitment to open communication and customer-centric approach has solidified its position as a trusted partner for prototyping services, earning the loyalty and trust of clients across the globe.Looking ahead, Prototyping China is poised to continue its expansion and further enhance its prototyping capabilities. The company remains dedicated to staying at the forefront of technological advancements and industry best practices, ensuring that it can continue to deliver the highest quality prototypes and exceed client expectations. With a focus on innovation, precision, and customer satisfaction, Prototyping China is well-positioned to lead the way in the ever-evolving world of prototyping.In conclusion, Prototyping China has solidified its position as a leader in providing top-tier prototyping solutions that cater to the diverse needs of its clients. With its commitment to excellence, cutting-edge capabilities, and customer-centric approach, Prototyping China continues to set new standards for the prototyping industry. As it expands its reach and enhances its capabilities, Prototyping China is poised to remain a trailblazer in the world of prototyping, offering unparalleled services to companies seeking to bring their innovative ideas to life.

3D Metal Parts Customization: Everything You Need to Know

Custom 3D Metal Parts Revolutionizing the Manufacturing IndustryIn today's fast-paced and ever-changing world, the demand for high-quality and precise metal parts is constantly growing. Traditional manufacturing processes often fall short in meeting this demand, leading to increased costs and production times. However, with the advent of 3D metal printing technology, the manufacturing industry is experiencing a revolutionary change.At the forefront of this change is [Company Name], a leading manufacturer of custom 3D metal parts. With years of experience and a dedication to innovation, the company has positioned itself as a pioneer in the field of additive manufacturing. By leveraging the power of cutting-edge 3D printing technology, [Company Name] has been able to produce highly intricate and complex metal parts with unparalleled precision and efficiency.Unlike traditional manufacturing methods, which often involve the use of costly and time-consuming tooling processes, 3D metal printing allows for the direct creation of parts from digital designs. This not only eliminates the need for complex tooling but also significantly reduces production times and costs. With 3D metal printing, [Company Name] is able to quickly and accurately produce custom metal parts, regardless of their complexity or size, with remarkable precision.Moreover, 3D metal printing offers a level of design flexibility and customization that was previously unattainable with traditional manufacturing processes. This has empowered [Company Name] to work closely with its clients to develop bespoke solutions that meet their exact specifications. Whether it's a one-of-a-kind prototype or a large-scale production run, [Company Name] has the capability to deliver custom 3D metal parts that are tailored to its customers' specific needs.The benefits of 3D metal printing extend beyond the production of intricate and customized parts. The technology also enables the creation of lightweight yet durable components, making it ideal for applications where weight reduction is critical. Furthermore, 3D metal printing allows for the production of parts with complex geometries and internal structures that would be impractical or impossible to achieve using traditional manufacturing methods.As the demand for custom metal parts continues to grow across various industries, [Company Name] is well-positioned to meet the needs of its customers. From aerospace and automotive to medical and consumer electronics, the company's 3D metal printing capabilities have enabled it to serve a diverse range of industries with unparalleled quality and precision.In order to ensure the highest standards of quality, [Company Name] utilizes advanced metal powders and state-of-the-art 3D printing equipment. This, combined with its team of highly skilled engineers and technicians, allows the company to consistently deliver custom 3D metal parts that meet the most stringent performance and reliability requirements.Moreover, [Company Name] remains committed to sustainability and environmental responsibility. By optimizing its manufacturing processes and reducing material waste, the company has been able to minimize its environmental footprint while still delivering superior metal parts to its customers.Looking ahead, the future of custom 3D metal parts manufacturing looks promising. With ongoing advancements in 3D printing technology and materials, the possibilities for creating complex and customized metal parts are virtually limitless. As a leader in the field, [Company Name] is dedicated to staying at the forefront of these advancements, ensuring that it continues to provide its customers with innovative and high-quality solutions.In conclusion, 3D metal printing has ushered in a new era of manufacturing, offering unprecedented levels of precision, customization, and efficiency. Through its cutting-edge capabilities and commitment to excellence, [Company Name] has established itself as a trusted partner for the production of custom 3D metal parts. As the industry continues to evolve, [Company Name] is poised to lead the way, driving innovation and delivering exceptional solutions to its customers.

Innovative Prototyping and Plastic Molding Techniques for Product Development

Prototype And Plastic Mold, a leading provider of high-quality plastic injection molds and prototype services, has been the go-to choice for companies seeking top-notch prototyping and mold solutions. With its state-of-the-art facilities and team of experienced professionals, the company has been able to deliver exceptional results to numerous clients across various industries.Founded in 1998, {Company Name} has established itself as a trusted partner for companies looking to bring their product ideas to life. The company prides itself on its ability to deliver top-quality plastic injection molds and prototypes with quick turnaround times. This has made them a preferred choice for many businesses looking to streamline their product development processes.One of the key factors that set {Company Name} apart from its competitors is its commitment to investing in the latest technology and machinery. The company's facility is equipped with advanced CNC machines, EDM equipment, and other cutting-edge tools that enable it to produce precise and high-quality molds and prototypes. This investment in technology has allowed {Company Name} to consistently meet and exceed the expectations of its clients.In addition to its technological capabilities, {Company Name} also boasts a team of highly skilled and experienced professionals. From design engineers to toolmakers, the company's staff is dedicated to ensuring that each project is executed with the utmost precision and attention to detail. This collaborative approach has enabled {Company Name} to build long-lasting relationships with its clients, many of whom rely on the company for their ongoing prototyping and mold needs.The company's specialization in plastic injection molds and prototypes has made it a valuable partner for companies in industries such as automotive, consumer goods, electronics, and medical devices. {Company Name}'s ability to cater to diverse sectors speaks to its adaptability and expertise in meeting the unique needs of each client. Whether it's a complex mold for a medical device or a high-precision prototype for an electronic component, {Company Name} has proven its ability to deliver time and time again.One of the standout offerings of {Company Name} is its ability to provide turnkey solutions to its clients. From concept development to design, prototyping, and production, the company is equipped to handle every stage of the product development process. This comprehensive approach has not only streamlined its clients' workflows but has also contributed to significant cost savings and accelerated time-to-market for their products.{Company Name} has also garnered a reputation for its unwavering commitment to quality and customer satisfaction. The company adheres to strict quality control measures throughout the manufacturing process, ensuring that every mold and prototype meets the highest standards. This dedication to quality has earned the trust and loyalty of its clients, many of whom rely on {Company Name} for their most critical projects.Looking ahead, {Company Name} is poised to continue its legacy of excellence in providing plastic injection molds and prototype services. With a focus on innovation and continuous improvement, the company is committed to staying at the forefront of the industry and meeting the evolving needs of its clients. As market demand for high-quality molds and prototypes continues to rise, {Company Name} is well-positioned to remain a leader in the industry.In conclusion, {Company Name} has established itself as a premier provider of plastic injection molds and prototypes, with a track record of delivering exceptional results for its clients. With its cutting-edge technology, experienced team, and unwavering commitment to quality, the company has solidified its position as a trusted partner for businesses across various industries. As it continues to innovate and expand its capabilities, {Company Name} is set to remain a go-to choice for companies seeking top-notch prototyping and mold solutions.

Durable and Lightweight Aluminum Cases: The Perfect Storage Solution

Aluminum Case Offers Superior Durability and Protection for Everyday UseAluminum cases are known for their superior durability and protection, making them an ideal choice for storing and transporting valuable items. Whether it's a delicate electronic device or important documents, an aluminum case provides unparalleled security and peace of mind. With its sleek and modern design, an aluminum case is the perfect combination of style and functionality.One company that is at the forefront of producing high-quality aluminum cases is {}. With over 20 years of experience in the industry, {} has established itself as a leading manufacturer of aluminum cases, catering to a wide range of industries and applications. From military and law enforcement to medical and industrial, {} offers a diverse range of aluminum cases to meet the unique needs of its customers.The key to {}'s success lies in its commitment to using only the highest quality materials and the latest manufacturing techniques. Each aluminum case is carefully designed to provide maximum protection and durability, ensuring that valuable items remain safe and secure at all times. Additionally, {} prides itself on its ability to customize aluminum cases to meet specific requirements, offering a level of personalization that is unmatched in the industry.One of the standout features of {}'s aluminum cases is their lightweight yet robust construction. Made from high-grade aluminum alloy, these cases are not only strong and impact-resistant but also lightweight and easy to carry. This makes them perfect for everyday use, whether it's for professional or personal purposes. Furthermore, the aluminum construction makes these cases resistant to corrosion and rust, ensuring that they maintain their quality and appearance over time.In addition to their durability, {}'s aluminum cases are designed with user convenience in mind. Thoughtful features such as secure locking mechanisms, ergonomic handles, and customizable foam interiors make these cases easy to use and highly functional. Whether it's for storing electronic equipment, firearms, or sensitive instruments, {}'s aluminum cases provide the level of protection and organization that is essential for demanding applications.With a focus on innovation and continuous improvement, {} is constantly exploring new ways to enhance the performance and design of its aluminum cases. By staying ahead of the curve and embracing the latest advancements in materials and production methods, {} ensures that its customers receive the most advanced and reliable aluminum cases on the market.In conclusion, {}'s aluminum cases are a testament to the company's unwavering dedication to quality, craftsmanship, and customer satisfaction. With their unmatched durability, innovative design, and customizable options, {}'s aluminum cases are the go-to choice for professionals and individuals who require the best in protection and security for their valuable items. As the demand for high-quality aluminum cases continues to grow, {} remains committed to setting the standard for excellence in the industry.

Top Tips for Plastic Mold Tooling

Plastic Mold Tooling (PMT) is a leading company in the industry, specializing in the design and manufacture of plastic injection molds and tooling. With over 20 years of experience, PMT has established a strong reputation for delivering high-quality molds and tooling solutions to a wide range of industries, including automotive, aerospace, medical, and consumer electronics.The company's state-of-the-art facility is equipped with the latest technology and machinery, allowing PMT to offer a comprehensive range of services, from initial concept and design through to production and finishing. PMT's team of highly skilled engineers and technicians work closely with clients to develop custom mold solutions that meet their specific requirements and exceed their expectations.One of PMT's key strengths is its commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly exploring new materials, processes, and technologies to enhance its product offerings. This dedication to innovation has enabled PMT to stay ahead of the curve and deliver cutting-edge mold and tooling solutions to its clients.PMT's dedication to quality is evident in its ISO 9001 certification, which reflects its commitment to upholding the highest standards of manufacturing excellence. The company's rigorous quality control processes ensure that every mold and tooling product that leaves its facility meets the most stringent quality requirements, guaranteeing reliable and consistent performance for its clients.PMT's customer-centric approach sets it apart in the industry. The company places a strong emphasis on building long-term partnerships with its clients, working collaboratively to understand their unique needs and deliver tailored solutions that help them achieve their business objectives. PMT's customer service team is known for its responsiveness, reliability, and flexibility, offering clients the support and assistance they need at every stage of their project.In addition to its technical expertise and commitment to quality, PMT also prides itself on its strong environmental stewardship. The company is dedicated to sustainable manufacturing practices, minimizing waste and energy consumption while maximizing the use of recyclable materials. PMT's environmentally friendly approach not only benefits the planet but also helps clients meet their own sustainability goals.Looking to the future, PMT is poised for continued success and growth. The company is committed to expanding its capabilities and market reach, leveraging its expertise to serve new industries and international markets. With a focus on innovation, quality, and customer satisfaction, PMT is well-positioned to remain a trusted partner for companies seeking top-notch mold and tooling solutions.As a testament to its success and reputation, PMT has received numerous accolades and industry recognition for its contributions to the field of plastic mold tooling. The company's track record of excellence speaks for itself, establishing PMT as a leader in the industry and a go-to partner for businesses seeking cutting-edge mold and tooling solutions.In conclusion, Plastic Mold Tooling (PMT) stands out as a top-tier provider of plastic injection molds and tooling solutions, serving a diverse range of industries with its innovative, high-quality products. With a strong focus on customer satisfaction, environmental responsibility, and continuous improvement, PMT is well-positioned for continued success and growth in the years to come.

Top Plastic Molding Services in China: A Complete Overview

Plastic Molding in China (Need Remove Brand Name): Pioneering Excellence in ManufacturingAs one of the leading manufacturers and suppliers of plastic molding in China, {} has been at the forefront of delivering high-quality products to various industries. With a strong focus on innovation, technology, and customer satisfaction, the company has established a solid reputation as a reliable and trusted partner for businesses seeking top-notch plastic molding solutions.Founded in the heart of China's manufacturing hub, {} has leveraged its strategic location to access a wide range of resources, including raw materials, skilled labor, and cutting-edge technology. This has allowed the company to stay ahead of the competition and consistently deliver superior products to its global clientele.One of the key factors that sets {} apart from its competitors is its state-of-the-art manufacturing facility, which is equipped with the latest machinery and tools for plastic molding. The company's commitment to investing in advanced technology has enabled it to streamline its production processes, enhance product quality, and meet the evolving needs of its customers.In addition to its technological prowess, {} takes great pride in its team of experienced engineers and technicians who possess in-depth knowledge of plastic molding techniques. These professionals work tirelessly to develop innovative solutions that cater to a diverse array of industries, including automotive, electronics, medical, and consumer goods.Furthermore, {} has set itself apart through its unwavering dedication to quality control and assurance. The company adheres to stringent international standards and protocols to ensure that every product that leaves its facility is of the highest caliber. This commitment to excellence has earned {} the trust and loyalty of its clients, who rely on the company to deliver superior plastic molding solutions that meet their exact specifications.Moreover, {} places a strong emphasis on sustainability and environmental responsibility. The company is conscious of its carbon footprint and actively seeks to minimize its impact on the environment. By adopting eco-friendly practices and implementing green initiatives, {} is dedicated to creating a more sustainable future for generations to come.Beyond its commitment to manufacturing excellence, {} is also renowned for its exceptional customer service. The company's team of dedicated professionals goes above and beyond to provide personalized support to clients, guiding them through every step of the manufacturing process and ensuring their complete satisfaction.Looking ahead, {} is poised to expand its global footprint and further solidify its position as a leading provider of plastic molding solutions. The company remains committed to continuous improvement and innovation, as it endeavors to meet the ever-evolving demands of the market and exceed the expectations of its customers.In conclusion, {} stands as a shining example of manufacturing excellence and commitment to customer satisfaction in the realm of plastic molding. With its cutting-edge technology, skilled workforce, unwavering dedication to quality, and focus on sustainability, the company is well-positioned to spearhead the future of the industry and set new benchmarks for success. For businesses seeking unparalleled plastic molding solutions, {} continues to be the partner of choice.

The Benefits of 3D Printing in Prototyping: Advantages and Applications

3D Printing In Prototyping3D printing technology has revolutionized the way products are prototyped and manufactured. With the ability to create precise and intricate designs, 3D printing has become an invaluable tool for companies across various industries. In particular, the use of 3D printing in prototyping has significantly reduced the time and cost associated with product development.One company that has been at the forefront of utilizing 3D printing in prototyping is {}. With a strong focus on innovation and cutting-edge technology, {} has been able to effectively leverage 3D printing to streamline their prototyping process and bring new products to market faster than ever before.The process of prototyping is a critical stage in product development, as it allows companies to test and refine their designs before moving into full-scale production. Traditionally, prototyping involved costly and time-consuming methods such as injection molding or CNC machining. However, with the advent of 3D printing, companies like {} have been able to significantly reduce the time and cost associated with prototyping.By utilizing 3D printing technology, {} has been able to rapidly produce prototypes of their products with a high degree of accuracy and detail. This has allowed the company to iterate and test different designs much more efficiently, ultimately leading to better final products. Additionally, the ability to quickly produce prototypes has given {} a competitive edge in their industry, allowing them to stay ahead of the curve and bring new products to market faster.One of the key advantages of 3D printing in prototyping is the ability to produce complex and intricate designs that would be difficult or impossible to create using traditional methods. This has allowed {} to push the boundaries of their product innovation, leading to the development of unique and highly functional designs that would not have been possible without 3D printing technology.Beyond prototyping, {} has also been able to use 3D printing for low-volume production, allowing them to quickly and cost-effectively produce small batches of their products for testing and market analysis. This has been a valuable tool for {} as they continue to develop and refine their product offerings.Looking ahead, {} sees 3D printing playing an even larger role in their product development process. The company is investing in advanced 3D printing technology and materials to further enhance their prototyping capabilities. They are also exploring the use of 3D printing for custom and on-demand manufacturing, which could open up new opportunities for the company to provide personalized products to their customers.Overall, the use of 3D printing in prototyping has been a game-changer for companies like {}. By embracing this cutting-edge technology, they have been able to streamline their prototyping process, reduce time to market, and bring innovative products to market faster than ever before. As 3D printing continues to evolve, it is poised to play an even larger role in the future of product development and manufacturing. And companies like {} are well-positioned to continue leading the way in leveraging this technology to drive innovation and success.

Effective CNC Production Techniques for Streamlined Manufacturing

Production CNC, a leading global manufacturer of CNC (computer numerical control) machines, has recently announced the launch of its latest innovative product line, aimed at revolutionizing the manufacturing industry.With over 20 years of experience in the industry, Production CNC has been at the forefront of developing cutting-edge technologies to meet the needs of modern manufacturing. The company's dedication to precision, efficiency, and durability has made it a trusted name in the industry.The new product line from Production CNC features state-of-the-art CNC machines that are designed to deliver unmatched precision and performance. These machines are equipped with advanced automation and control systems, allowing for seamless integration into modern manufacturing processes. The company's commitment to innovation and quality is evident in every aspect of the new product line, from design to production.One of the standout features of the new product line is its versatility. Whether it's a small-scale job or a large-scale production run, Production CNC's machines are capable of handling a wide range of manufacturing needs. This flexibility makes them an ideal choice for businesses looking to streamline their production processes and improve overall efficiency.In addition to their impressive performance capabilities, the new CNC machines from Production CNC are also designed with user-friendly features that make them easy to operate and maintain. This focus on usability reflects the company's commitment to providing practical solutions that empower manufacturers to achieve their production goals with ease.Furthermore, Production CNC is dedicated to sustainability and reducing environmental impact. The new product line includes energy-efficient machines that are designed to minimize energy consumption without compromising performance. This demonstrates the company's forward-thinking approach to developing solutions that not only benefit manufacturers but also contribute to a more sustainable future.To support the launch of the new product line, Production CNC has also expanded its customer support and service offerings. The company's team of experienced technicians and engineers are available to provide comprehensive training, technical support, and maintenance services to ensure that customers are able to maximize the potential of their CNC machines."Production CNC is proud to introduce our latest product line, which has been engineered to set new industry standards for precision, efficiency, and reliability," said the company's CEO. "We believe that these machines will empower manufacturers to achieve greater productivity and competitiveness in today's fast-paced market. We are committed to providing our customers with the tools and support they need to succeed, and we are excited to bring this game-changing technology to the global manufacturing community."With its unwavering commitment to innovation, quality, and customer satisfaction, Production CNC continues to be a driving force in the manufacturing industry. The company's new product line is poised to make a significant impact, setting a new benchmark for CNC machines and ushering in a new era of manufacturing excellence. As the industry continues to evolve, Production CNC remains dedicated to leading the way with cutting-edge solutions that empower manufacturers to thrive in an ever-changing market.

Sintered 3D Laser Printing: A Revolutionary Additive Manufacturing Technology

Sintered laser printing, also known as Selective Laser Sintering (SLS), is a revolutionary 3D printing technology that is rapidly gaining popularity in the manufacturing industry. This advanced additive manufacturing process involves the use of a high-powered laser to selectively sinter powdered material, such as nylon, into a solid 3D structure. The result is a highly durable and precise part that can be used in a wide range of applications, from prototyping and tooling to end-use production. One company at the forefront of this cutting-edge technology is {}.{} is a leading provider of innovative 3D printing solutions, and their SLS technology is setting new standards for speed, quality, and cost-effectiveness. Their state-of-the-art SLS machines are capable of producing complex parts with intricate geometries and fine details, making them ideal for a variety of industries, including aerospace, automotive, medical, and consumer goods.One of the key advantages of {}’s SLS technology is its ability to produce parts with high strength and stability. This makes it suitable for producing functional prototypes and end-use parts that require exceptional mechanical properties. Furthermore, the SLS process allows for the production of parts with no need for support structures, reducing material waste and post-processing time. As a result, {}’s SLS technology offers significant advantages over traditional manufacturing methods, such as injection molding and CNC machining.In addition to its technical capabilities, {}’s SLS technology is also known for its speed and efficiency. With the ability to produce multiple parts in a single build, the company’s SLS machines can dramatically reduce lead times and production costs. This makes it an attractive option for businesses looking to streamline their manufacturing processes and bring new products to market faster.Furthermore, {} offers a wide range of materials for SLS printing, including industrial-grade nylon, and high-performance engineering polymers. This allows their customers to choose the material that best suits their specific application requirements, whether it’s for functional prototypes, end-use parts, or low-volume production runs.Moreover, {} not only provides cutting-edge SLS technology but also offers comprehensive support and expertise to its customers. From design optimization and material selection to post-processing and finishing, {}’s team of experts works closely with their clients to ensure the success of their SLS printing projects.With a proven track record of delivering high-quality parts and exceptional customer service, {} has established itself as a trusted partner for businesses seeking the benefits of SLS technology. From rapid prototyping to on-demand manufacturing, {}’s SLS capabilities are helping companies across various industries innovate and thrive in today’s competitive marketplace.In conclusion, Sintered Laser Printing, or Selective Laser Sintering, is revolutionizing the manufacturing industry, and {} is leading the way with their advanced SLS technology. With its exceptional strength, speed, and versatility, {}’s SLS technology is empowering businesses to bring their ideas to life in ways that were previously not possible. As 3D printing continues to evolve, {} remains committed to pushing the boundaries of what’s possible and helping their customers achieve new levels of success.