Innovative Medical Device Prototype Revealed in Latest News

By:Admin

Medical technology has advanced by leaps and bounds in recent years, with new devices and innovations consistently being introduced to improve patient care and outcomes. One such advancement is the development of a groundbreaking medical device prototype by the innovative team at {Company}, a leading medical technology company.

{Company} is a global leader in medical device development, specializing in cutting-edge technology that aims to improve the lives of patients and healthcare professionals. With a strong focus on research and development, {Company} has consistently delivered innovative solutions that address the most pressing needs in the healthcare industry.

The latest achievement from {Company} is a medical device prototype that is set to revolutionize the way certain medical conditions are diagnosed and treated. The prototype, which is currently in the testing phase, has the potential to significantly improve patient outcomes and streamline the diagnostic process for healthcare providers.

One of the most striking features of the medical device prototype is its ability to provide accurate and real-time data, allowing healthcare professionals to make informed decisions quickly and effectively. This can be especially crucial in emergency situations where time is of the essence, and quick diagnosis and intervention can be life-saving.

Additionally, the prototype is designed with patient comfort and convenience in mind. The team at {Company} has prioritized the development of a device that is user-friendly and non-invasive, ensuring that patients feel at ease during the diagnostic and treatment process.

The potential applications for the medical device prototype are wide-reaching, with implications for a variety of medical specialties. From cardiology to neurology, the device has the potential to enhance clinical practice and improve patient care across the board.

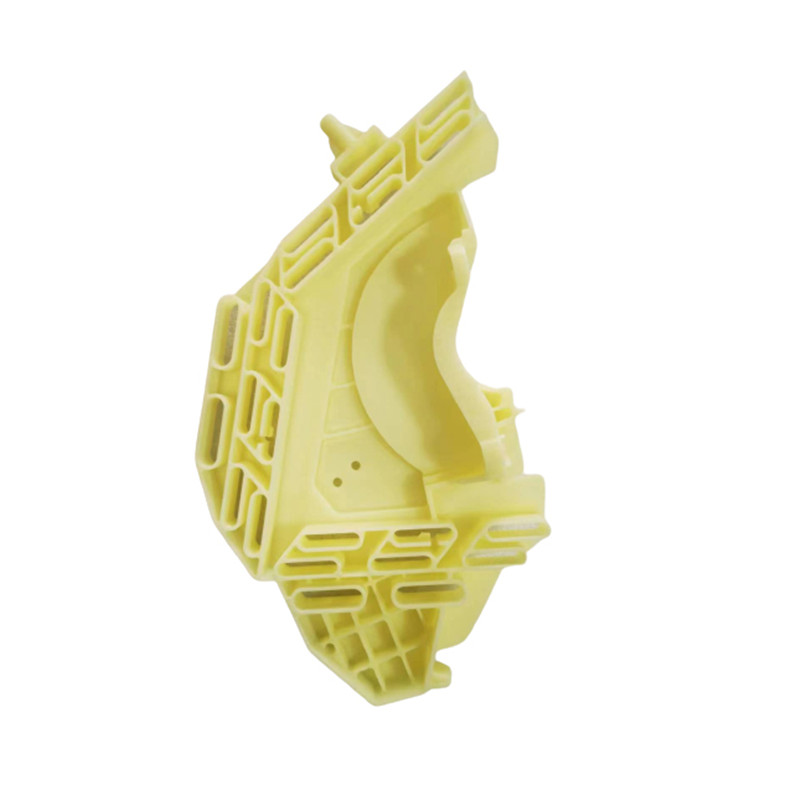

In addition to its remarkable functionality, the prototype also represents a significant leap forward in terms of design and engineering. The team at {Company} has worked tirelessly to ensure that the device is not only highly effective but also practical and durable, making it a valuable asset for healthcare facilities of all sizes.

The development of the medical device prototype is a testament to {Company}'s commitment to pushing the boundaries of medical technology and driving innovation in healthcare. With a team of dedicated professionals and a culture of continuous improvement, {Company} has positioned itself as a leader in the field of medical device development, consistently delivering solutions that make a real difference in the lives of patients and healthcare providers.

Looking ahead, {Company} is poised to continue its trajectory of success, with an impressive pipeline of new projects and innovations on the horizon. The medical device prototype is just one example of the company's dedication to advancing healthcare through technology, and there is no doubt that {Company} will continue to make significant contributions to the field in the years to come.

As the medical device prototype moves closer to commercialization, the team at {Company} remains dedicated to ensuring that it meets the highest standards of quality, safety, and efficacy. With the potential to transform the way certain medical conditions are diagnosed and treated, the prototype represents a significant step forward in the quest to improve patient care and outcomes.

In conclusion, {Company}'s medical device prototype is a remarkable achievement that has the potential to revolutionize healthcare. With its innovative design, advanced functionality, and broad applications, the prototype is set to make a significant impact on the way medical conditions are diagnosed and treated. As {Company} continues to drive innovation in the field of medical technology, it is clear that the future of healthcare is in good hands.

Company News & Blog

Ultimate Guide to SLS 3D Printing Materials: A Complete Overview

The 3D printing industry has been rapidly evolving over the years, and one of the key players in this space is {company}. They are known for their innovative SLS 3D printing materials, which have been making waves in the industry. These materials have been utilized in various industries, from aerospace to automotive, due to their high-quality and durable properties.{Company} is a leading provider of advanced materials and additive manufacturing solutions. They have a strong focus on creating materials that are not only functional but also environmentally friendly. With a passion for innovation and sustainability, {company} has been at the forefront of driving the 3D printing industry forward.Their SLS 3D printing materials have been a game-changer for many businesses. SLS, or selective laser sintering, is a 3D printing technology that uses a high-powered laser to fuse small particles of polymer powders into a solid structure. This process allows for the creation of complex and intricate designs that would be difficult or impossible to achieve using traditional manufacturing methods.{Company}'s SLS 3D printing materials are known for their high strength and durability, making them ideal for a wide range of applications. They have been used in the production of end-use parts, functional prototypes, and even low-volume manufacturing. The materials are also resistant to high temperatures and have excellent mechanical properties, making them suitable for demanding environments.One of the key advantages of {company}'s SLS 3D printing materials is their versatility. They can be used with a wide range of SLS 3D printers, allowing businesses to choose the best solution for their specific needs. This flexibility has made {company}'s materials a popular choice for companies looking to leverage the benefits of 3D printing.Furthermore, {company} is committed to sustainability and has developed SLS 3D printing materials that are eco-friendly. They have focused on reducing waste and energy consumption in the manufacturing process, while also ensuring that their materials are recyclable. This commitment to sustainability has resonated with many businesses looking to minimize their environmental impact.In addition to their SLS 3D printing materials, {company} also offers a range of support services to help businesses integrate 3D printing into their operations. They provide expertise in material selection, process optimization, and post-processing techniques, ensuring that businesses can fully leverage the benefits of additive manufacturing.{Company} has also invested in research and development to continuously improve their SLS 3D printing materials. They are constantly testing new materials and optimizing their formulations to meet the evolving needs of the industry. This dedication to innovation has solidified their position as a leader in the 3D printing materials space.As the 3D printing industry continues to grow, {company} is well-positioned to capitalize on the increasing demand for high-quality materials. Their SLS 3D printing materials have already made a significant impact on the industry, and with their ongoing commitment to innovation and sustainability, they are poised to remain at the forefront of the industry for years to come.In conclusion, {company} has established itself as a leading provider of SLS 3D printing materials, with a strong focus on innovation, sustainability, and customer support. Their materials have been instrumental in driving the adoption of 3D printing in various industries, and they continue to push the boundaries of what is possible with additive manufacturing. With a track record of success and a dedication to excellence, {company} is well-positioned to shape the future of the 3D printing industry.

Ultimate Guide to Mould Plastic Injection: Everything you Need to Know

Mould Plastic Injection, a leading company in the plastic molding industry, is making waves with its innovative approach to injection molding. With a strong emphasis on quality, precision, and efficiency, the company has quickly established itself as a trusted partner for businesses looking to bring their plastic products to market.Established in [year], Mould Plastic Injection has steadily grown its operations and now boasts a state-of-the-art facility equipped with the latest technology in injection molding. The company prides itself on its ability to deliver high-quality plastic components with tight tolerances and complex geometries, catering to a wide range of industries including automotive, medical, consumer goods, and electronics.One of the key factors that set Mould Plastic Injection apart from its competitors is its unwavering commitment to customer satisfaction. The company works closely with its clients from the initial design phase through to production, ensuring that all specifications and requirements are met with precision. By offering comprehensive design assistance and rapid prototyping services, Mould Plastic Injection enables its clients to bring their products to market quickly and efficiently.In addition to its dedication to customer service, Mould Plastic Injection places a strong emphasis on technological innovation. The company continually invests in the latest machinery and equipment to optimize its manufacturing processes, ultimately leading to higher productivity and cost efficiency. This commitment to innovation has allowed Mould Plastic Injection to stay ahead of the curve in an increasingly competitive industry.Furthermore, Mould Plastic Injection is also committed to sustainability and environmental responsibility. The company has implemented various initiatives to minimize waste and reduce its carbon footprint, ensuring that its manufacturing processes are as eco-friendly as possible. By prioritizing sustainability, Mould Plastic Injection not only benefits the environment but also demonstrates its dedication to corporate social responsibility.Mould Plastic Injection's dedication to quality, innovation, customer service, and sustainability has not gone unnoticed in the industry. The company has received numerous accolades and certifications for its outstanding performance and commitment to excellence. Its growing list of satisfied clients is a testament to its ability to consistently deliver exceptional results.Looking ahead, Mould Plastic Injection is poised for continued growth and success. The company remains focused on expanding its capabilities, embracing new technologies, and exploring new opportunities to serve a broader customer base. With its unwavering commitment to excellence and innovation, Mould Plastic Injection is well-positioned to remain a leader in the plastic molding industry for years to come.

Quality CNC Parts: The Ultimate Guide to OEM Manufacturing

OEM CNC Parts - A Valuable Addition to the Manufacturing IndustryIn today's fast-paced and highly competitive manufacturing industry, the demand for high-quality, precise, and cost-effective components is greater than ever. This is where OEM CNC parts come into play, offering manufacturers a valuable solution to their production needs. With the ability to produce intricate and complex parts with unparalleled accuracy, OEM CNC parts are becoming an essential component in the manufacturing process.One company that has made a significant impact in this industry is {}. With a strong focus on precision engineering and advanced manufacturing technologies, they have established themselves as a leading provider of OEM CNC parts. From prototype development to large-scale production, {} offers a wide range of CNC machining services tailored to meet the specific needs of their clients.The use of Computer Numerical Control (CNC) technology has revolutionized the manufacturing process, allowing for the production of complex parts with extreme accuracy and repeatability. OEM CNC parts are produced from a wide variety of materials, including metals, plastics, and composites, making them suitable for a diverse range of applications across industries such as aerospace, automotive, medical, and electronics.One of the key advantages of OEM CNC parts is their ability to deliver consistent quality and precision, ensuring that each component meets the exact specifications required. This level of precision is essential in industries where safety, reliability, and performance are paramount, and it is a primary reason why manufacturers are turning to OEM CNC parts to meet their production needs.In addition to precision, OEM CNC parts offer manufacturers the flexibility to create custom components with complex geometries and intricate features. This level of customization allows for the production of parts that were previously unattainable using conventional manufacturing methods, opening up new opportunities for innovation and design in the industry.Another significant benefit of OEM CNC parts is the potential for cost savings. By streamlining the manufacturing process and reducing the need for additional tooling and equipment, OEM CNC parts can help manufacturers minimize production costs while maintaining high-quality standards. This is particularly advantageous for companies looking to minimize waste and optimize their production processes.As the demand for high-quality, precision components continues to grow, {} has positioned itself as a trusted partner for manufacturers seeking OEM CNC parts. With state-of-the-art facilities and a team of highly skilled engineers and machinists, {} is committed to delivering top-quality CNC machining solutions that meet the rigorous demands of the industry.In conclusion, OEM CNC parts have become an invaluable asset to the manufacturing industry, providing manufacturers with the precision, flexibility, and cost-effectiveness they need to stay competitive in today's market. As the industry continues to evolve, it is clear that OEM CNC parts will play a crucial role in shaping the future of manufacturing, and companies like {} are at the forefront of this innovation, offering comprehensive CNC machining solutions to meet the diverse needs of their clients.

Custom CNC Machining Services for Prototypes and Production Parts

Prototyping Machining, a leading machining and manufacturing company, has announced the launch of their latest prototype machining services. The company, known for its dedication to precision and quality, is excited to offer this new service to meet the growing demands of their customers in various industries.With a state-of-the-art facility and a team of experienced engineers and technicians, Prototyping Machining has become a trusted name in the manufacturing industry. The company specializes in providing high-quality machining and manufacturing solutions to a wide range of businesses, from automotive and aerospace to medical and consumer products.The new prototype machining services will further enhance Prototyping Machining's ability to provide innovative and efficient solutions to their clients. By utilizing advanced technologies and industry-leading techniques, the company is committed to delivering top-notch prototype parts and components that meet the exact specifications of their customers."We're thrilled to introduce our new prototype machining services to our valued clients," said [company spokesperson]. "This expansion is a testament to our ongoing commitment to providing the best possible solutions to meet the evolving needs of the industries we serve. Our team has worked tirelessly to ensure that our prototype machining capabilities are second to none, and we are excited to see the impact it will have on our clients' projects."Prototyping Machining's comprehensive prototype machining services include CNC machining, 3D printing, rapid prototyping, and custom part manufacturing. The company's advanced equipment and expertise allow them to create complex and intricate prototype parts with tight tolerances and precision.In addition to their cutting-edge technology, Prototyping Machining also prides themselves on their rapid turnaround times and competitive pricing. They understand the importance of getting prototypes into the hands of their clients quickly, and they are dedicated to providing efficient and cost-effective solutions without compromising on quality.Furthermore, Prototyping Machining's team of engineers and technicians work closely with their clients throughout the prototype machining process. From initial design and development to final production, the company offers personalized support and expertise to ensure that every project is a success.With their new prototype machining services, Prototyping Machining is prepared to take on a wide range of prototype projects, from small-scale components to large and complex parts. Their commitment to excellence and customer satisfaction positions them as a premier choice for businesses looking for reliable and high-quality prototype machining solutions."We are confident that our new prototype machining services will be a game-changer for our clients," added [company spokesperson]. "We understand the pivotal role that prototypes play in the development and production of new products, and we are dedicated to delivering exceptional results that meet and exceed our clients' expectations."As Prototyping Machining continues to expand their capabilities and services, they remain committed to upholding the highest standards of quality and precision. With their new prototype machining services, the company is poised to further solidify their position as a leading provider of advanced machining and manufacturing solutions.For businesses looking for reliable and innovative prototype machining services, Prototyping Machining is the trusted partner to turn to. With their expertise, state-of-the-art facility, and unwavering dedication to excellence, the company is well-equipped to handle the most challenging and intricate prototype projects.

Advanced Laser Sintering Technology for 3D Printing Applications

{Company Name} is a leading provider of advanced manufacturing solutions that employs state-of-the-art technologies to cater to the needs of industries such as aerospace, automotive, healthcare, and consumer goods. The company is at the forefront of innovation in the field of additive manufacturing, constantly pushing the boundaries of what is possible when it comes to producing high-quality, complex parts and components.One of the technologies that has been instrumental in positioning {Company Name} as an industry leader is SLS (Selective Laser Sintering), a form of additive manufacturing that uses a high-powered laser to sinter powdered material, typically nylon or other polymers, layer by layer to create durable parts and components. SLS is known for its ability to produce parts with a high degree of accuracy, excellent mechanical properties, and the capacity to handle complex geometries, making it an ideal solution for rapid prototyping and low-volume production.{Company Name} has recently made significant advancements in SLS technology, further enhancing its capabilities and expanding the range of applications for which it can be utilized. The integration of advanced software and hardware solutions has enabled {Company Name} to achieve greater precision and efficiency in the SLS process, ultimately leading to improved part quality and reduced production times.With these developments, {Company Name} is poised to meet the growing demand for SLS-produced parts across various industries. The aerospace sector, in particular, stands to benefit from the enhanced capabilities of {Company Name}'s SLS technology, as it can now produce lightweight yet durable components that are critical for aircraft performance and safety. In the automotive industry, the ability to quickly iterate and produce functional prototypes using SLS is invaluable for accelerating product development cycles and bringing new vehicles to market faster.Furthermore, the healthcare industry can leverage {Company Name}'s advanced SLS technology to produce patient-specific medical devices and implants, providing personalized solutions that are tailored to individual needs. This has the potential to significantly improve patient outcomes and revolutionize the field of medical technology.In addition to technical advancements, {Company Name} has also focused on sustainability in its SLS manufacturing processes. By optimizing material usage and reducing waste, the company has made significant strides in minimizing its environmental footprint while still delivering high-quality parts to its customers.{Company Name} has invested heavily in research and development to continue pushing the boundaries of what is achievable with SLS technology. By collaborating with industry partners and academic institutions, the company has been able to stay ahead of the curve and anticipate the needs of its customers, ensuring that its SLS solutions remain at the forefront of the additive manufacturing landscape.Looking ahead, {Company Name} is committed to further expanding the capabilities of SLS to address new applications and industries. With a strong focus on innovation and customer satisfaction, the company is well-positioned to continue leading the way in advanced manufacturing solutions and solidify its reputation as a trusted partner for businesses looking to harness the power of additive manufacturing.

Top 3 Advantages of 3D Printing Metal Parts

Metal 3D printing is revolutionizing the way companies manufacture parts and products, and leading the charge in this cutting-edge technology is [company]. With their advanced metal 3D printing capabilities, [company] is breaking new ground and setting a new standard for precision, quality, and efficiency in the manufacturing industry.Utilizing state-of-the-art metal 3D printing technology, [company] is able to create complex metal parts with unprecedented precision and intricacy. This technology allows for the production of parts that were previously thought to be impossible to manufacture, opening up a world of new possibilities for engineers and designers. From intricate aerospace components to durable automotive parts, [company] is at the forefront of creating high-quality metal parts that meet the strictest industry standards.One of the key advantages of metal 3D printing is the ability to produce parts with unparalleled precision. Traditional manufacturing methods often result in small imperfections and inconsistencies in metal parts, but with 3D printing, [company] is able to create flawless, high-precision components that meet the exact specifications of their customers. This level of precision is essential in industries such as aerospace and medical, where even the smallest deviation from the intended design can have far-reaching consequences.In addition to precision, metal 3D printing also allows for the creation of highly complex parts that would be extremely difficult, if not impossible, to produce using traditional methods. The ability to create intricate lattices, internal structures, and unique geometries gives engineers and designers the freedom to explore new design possibilities and push the boundaries of what is possible in metal manufacturing.[Company]'s metal 3D printing capabilities also offer significant efficiencies in the manufacturing process. By eliminating the need for traditional tooling and machining, [company] is able to reduce lead times and production costs, resulting in faster turnaround times and more cost-effective solutions for their customers. This streamlined manufacturing process also reduces material waste, making metal 3D printing a more sustainable and environmentally friendly option for producing metal parts.As a leader in metal 3D printing, [company] is dedicated to pushing the boundaries of what is possible in metal manufacturing. Their team of skilled engineers and technicians are constantly innovating and developing new techniques to further improve the quality and capabilities of their metal 3D printing technology. By staying at the forefront of this rapidly evolving industry, [company] is able to provide their customers with the most advanced and cutting-edge solutions for their metal manufacturing needs.With their commitment to quality, precision, and innovation, [company] is redefining the metal manufacturing industry with their advanced metal 3D printing capabilities. By leveraging the power of this revolutionary technology, [company] is able to produce high-quality metal parts with unmatched precision and complexity, setting a new standard for the industry. As the demand for metal 3D printed parts continues to grow across a wide range of industries, [company] is well-positioned to lead the way in providing innovative and cost-effective solutions for their customers.

Precision CNC Service in China for High-Quality Manufacturing

China CNC Service Expands Operations to Meet Growing DemandChina CNC Service, a leading provider of CNC machining and manufacturing services, has announced the expansion of its operations to meet the growing demand for its high-quality products and services. The company, which specializes in precision machining, has established itself as a trusted partner for businesses in a wide range of industries, including aerospace, automotive, and medical device manufacturing.The expansion of China CNC Service's operations comes as the company continues to experience strong demand from both domestic and international customers. With the global manufacturing industry undergoing a period of rapid growth and innovation, there has been an increased need for reliable and efficient CNC machining services. In response to this demand, China CNC Service has expanded its production capacity and bolstered its workforce to ensure that it can continue to meet the needs of its customers.In addition to expanding its production capacity, China CNC Service has also invested in the latest CNC machining technology to further enhance its capabilities. The company's state-of-the-art facilities are equipped with advanced CNC milling and turning machines, as well as a range of other cutting-edge equipment. This investment in technology will allow China CNC Service to deliver even greater precision and efficiency in its machining processes, ultimately leading to higher-quality products for its customers.Furthermore, China CNC Service has also made strategic investments in its quality control and inspection processes to ensure that every product that leaves its facilities meets the highest standards of excellence. This commitment to quality has helped the company to build a strong reputation for reliability and consistency, earning the trust of its customers in an increasingly competitive market.With these expansions and investments, China CNC Service is well-positioned to continue its growth trajectory and meet the evolving needs of the manufacturing industry. The company's dedication to innovation, quality, and customer satisfaction sets it apart in the market, and its continued expansion signals its commitment to staying at the forefront of the CNC machining industry.As part of its expansion plans, China CNC Service has also prioritized sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations, including waste reduction and energy efficiency initiatives. By embracing sustainable manufacturing practices, China CNC Service is not only protecting the environment but also meeting the expectations of its customers, who increasingly value ethical and environmentally conscious business partners.In addition to its domestic expansion, China CNC Service is also exploring opportunities to further expand its international presence. With a growing number of customers from around the world seeking out its services, the company is looking to establish strategic partnerships and distribution channels to better serve its global clientele. By expanding its reach and increasing its accessibility to customers worldwide, China CNC Service aims to solidify its position as a leading CNC machining service provider on the global stage.Overall, the expansion of China CNC Service's operations represents a significant milestone for the company and underscores its commitment to meeting the needs of its customers in a rapidly evolving manufacturing landscape. With its investments in technology, quality control, and sustainability, China CNC Service is well-equipped to meet the growing demand for high-quality CNC machining services, both at home and abroad. As the company continues on its growth trajectory, it is poised to remain a key player in the industry, delivering precision-engineered solutions to businesses across a wide range of sectors.

High-Quality CNC Machine Turning Services for Precision Parts

The manufacturing industry has seen a rise in the use of advanced technology to improve production processes and increase efficiency. One of the most significant advancements in this industry is the use of CNC Machine Turning. This technology has revolutionized the way companies manufacture products, and it has become an essential tool for many businesses seeking to stay competitive in today's market.CNC Machine Turning, also known as computer numerical control machining, is the process of using computer-aided design (CAD) software to control and automate the movement of precision machining tools in order to create custom parts and components. This technology allows for precise and complex shapes to be created with high accuracy and consistency, making it a vital tool for industries like aerospace, automotive, and medical device manufacturing.At the forefront of this technological advancement is {Company Name}. Founded in 1995, {Company Name} has been a leader in providing precision machining solutions to its customers. With a focus on innovation and quality, {Company Name} has established itself as a go-to source for CNC machine turning services, offering a wide range of capabilities to meet the diverse needs of its clients.Having invested in state-of-the-art CNC machine turning equipment, {Company Name} has positioned itself as a leading provider of precision components for various industries. The company's commitment to continuous improvement and technological advancement has allowed it to stay ahead of the competition and provide its customers with high-quality, reliable products.{Company Name} takes pride in its ability to work with a variety of materials, including stainless steel, aluminum, brass, and plastics, to create custom components to exact specifications. Its team of skilled engineers and machinists is dedicated to ensuring that every product meets the highest standards of quality and precision.In addition to its CNC machine turning capabilities, {Company Name} also offers a range of other services, including milling, drilling, tapping, and assembly. This comprehensive approach allows the company to provide complete solutions to its customers, from initial design and prototyping to full-scale production and assembly.With a focus on customer satisfaction and a dedication to exceeding expectations, {Company Name} has built a reputation for delivering high-quality products and exceptional service. The company's commitment to excellence has earned it the trust of many leading companies in the aerospace, automotive, and medical industries, among others.In a rapidly evolving and competitive market, staying ahead of the curve is crucial for success. By investing in advanced technology and continuously improving its processes, {Company Name} has positioned itself as a leader in the precision machining industry. Its commitment to quality, innovation, and customer satisfaction sets it apart as a trusted partner for businesses seeking reliable and efficient CNC machine turning services.As the demand for precision components continues to grow, {Company Name} is well-positioned to meet the needs of its customers and provide them with the highest quality products and services. With its expertise in CNC machine turning and its dedication to excellence, the company is poised to continue its success and remain a leader in the industry for years to come.

Custom CNC Production Service: Everything You Need to Know

It has never been easier for companies to access high-quality CNC production services, thanks to the innovative solutions offered by {}. With a strong focus on precision engineering and cutting-edge technology, they have established themselves as a leading provider of CNC production services for a wide range of industries.The company utilizes state-of-the-art CNC machines to offer a full suite of production services, including milling, turning, and grinding. Their team of highly skilled engineers and technicians are able to work with a variety of materials, such as metals, plastics, and composites, to deliver parts and components that meet the exact specifications of their clients.One of the key advantages of partnering with {} is their ability to provide fast turnaround times without compromising on quality. Their advanced production facilities and streamlined processes enable them to efficiently produce parts in small to large quantities, making them an ideal partner for both prototyping and production runs.In addition to their technical capabilities, {} is also committed to providing excellent customer service. They work closely with their clients to understand their unique needs and challenges, and then tailor their production services to deliver optimal results. This approach has earned them a strong reputation for reliability and professionalism within the industry.Moreover, their dedication to innovation and continuous improvement is evident in their investment in the latest CNC technology. By staying at the forefront of advancements in machining and production, they are able to offer their clients access to the most cutting-edge solutions available in the market.Furthermore, the company is deeply committed to quality control and assurance. They have implemented rigorous inspection and testing processes throughout their production cycle to ensure that all parts and components meet the highest standards of precision and accuracy.Their dedication to quality has resulted in numerous certifications and awards, further solidifying their position as a trusted provider of CNC production services.With a strong track record of success and a growing list of satisfied clients, {} is poised to continue its expansion and become a dominant force in the CNC production industry.In conclusion, {} is a company that stands out for its commitment to excellence, innovation, and customer satisfaction. Their comprehensive range of CNC production services, coupled with their technical expertise and dedication to quality, make them an ideal partner for companies seeking reliable and high-quality manufacturing solutions. As they continue to grow and innovate, they are set to play a pivotal role in shaping the future of CNC production.

High-Quality Injection Mold for Precise CNC Machining Operations

In the world of manufacturing, precision and efficiency are of utmost importance. Recognizing this, many companies are turning to CNC injection molding as a way to produce high-quality products with minimal room for error. One company that has made significant strides in this area is [Company Name], a leader in the field of CNC injection molding technology.[Company Name] has been at the forefront of CNC injection molding for over a decade, utilizing state-of-the-art technology and a team of highly skilled engineers to deliver top-notch products to its clients. The company’s commitment to innovation and quality has set it apart from competitors, earning it a reputation as a trusted partner in the manufacturing industry.CNC injection molding is a manufacturing process in which molten material, typically plastic, is injected into a mold at high pressure. The material is then cooled and solidified, resulting in a finished product that is precise and reliable. This process is ideal for producing parts and components that require tight tolerances and complex geometries, making it a popular choice for industries such as automotive, medical devices, and consumer goods.One of the key advantages of CNC injection molding is its ability to produce large volumes of parts with consistent quality. This is particularly important for companies that require high-volume production runs, as it helps to reduce costs and ensure that every part meets the same exacting standards. Additionally, CNC injection molding allows for the use of a wide range of materials, giving manufacturers the flexibility to choose the best material for the specific needs of their products.[Company Name] has honed its expertise in CNC injection molding, offering clients a full range of services, from design and prototyping to production and finishing. The company’s advanced CNC machines and dedicated team of engineers enable it to tackle even the most challenging projects, delivering results that exceed client expectations.In addition to its technical capabilities, [Company Name] prides itself on its commitment to customer satisfaction. The company works closely with clients to understand their unique requirements and offers tailored solutions that meet their needs. With a focus on open communication and transparency, [Company Name] has built strong, long-lasting relationships with its clients, becoming a go-to partner for CNC injection molding projects.As [Company Name] continues to expand its capabilities, it remains committed to staying ahead of the curve in CNC injection molding technology. The company invests in research and development, constantly seeking new ways to improve its processes and deliver even better results to clients. This dedication to innovation has allowed [Company Name] to remain at the forefront of the industry, setting new standards for precision and quality in CNC injection molding.Looking ahead, [Company Name] is poised to continue its growth and leadership in the CNC injection molding market. With a focus on excellence and a passion for pushing the boundaries of what is possible, the company is well-positioned to meet the evolving needs of the manufacturing industry and provide clients with the highest quality products.In conclusion, CNC injection molding is a vital part of modern manufacturing, enabling companies to produce high-quality parts with precision and efficiency. [Company Name] has established itself as a leader in this field, combining cutting-edge technology with a customer-centric approach to deliver outstanding results. As CNC injection molding technology continues to evolve, [Company Name] is poised to remain at the forefront, setting new standards for excellence in the industry.