Top Aluminum Products: A Comprehensive Guide for Buyers

By:Admin

{Company name} is a leading manufacturer and distributor of aluminum products in the industry. With years of experience and expertise in the production and distribution of high-quality aluminum products, the company has established a strong reputation for providing top-notch products to its customers.

[News Content]

In the ever-evolving world of construction and manufacturing, the demand for high-quality aluminum products continues to grow. {Company name}, a leading aluminum product manufacturer, has recently announced the launch of its latest line of innovative aluminum products, aiming to meet the increasing demands of the industry.

The new range of aluminum products introduced by {Company name} includes a variety of items designed to cater to the diverse needs of its customers. From aluminum sheets and coils to extrusions and custom-made products, the company offers a comprehensive range of solutions for various applications in construction, transportation, and other industries.

One of the key highlights of the new product line is the introduction of advanced aluminum alloys that boast superior strength, durability, and corrosion resistance. These alloys are specifically engineered to meet the demanding requirements of modern construction and manufacturing projects, offering customers a reliable and cost-effective solution for their aluminum needs.

In addition to the premium quality of its products, {Company name} takes pride in its commitment to sustainability and environmental responsibility. The company ensures that its manufacturing processes adhere to strict environmental standards, minimizing its carbon footprint and promoting a greener, more sustainable future for the industry.

Furthermore, {Company name} places a strong emphasis on customer satisfaction and aims to provide exceptional service to its clients. With a team of experienced professionals and a dedication to meeting customer needs, the company offers personalized solutions and technical support to ensure that its customers receive the best possible products and service.

In a statement regarding the new product launch, the CEO of {Company name} expressed enthusiasm for the company's latest offerings and the potential impact they will have on the industry. "We are excited to introduce our new line of aluminum products, which showcases our ongoing commitment to innovation and excellence. With these new offerings, we aim to meet the evolving needs of our customers and provide them with the highest quality aluminum solutions available in the market," said the CEO.

{Company name} continues to lead the way in the aluminum industry, driving innovation and setting new standards for product quality and customer service. With its latest product launch, the company reaffirms its position as a reliable partner for businesses seeking top-notch aluminum solutions for their projects.

In conclusion, the launch of {Company name}'s latest line of aluminum products represents a significant milestone for the company and the industry as a whole. With its focus on innovation, sustainability, and customer satisfaction, {Company name} is poised to make a lasting impact on the market for aluminum products, providing customers with exceptional solutions for their construction and manufacturing needs.

Company News & Blog

What Are Swiss Turn Machines and How Do They Work?

Swiss Turn, a leading manufacturer of high-precision components, has recently made headlines in the manufacturing industry with its innovative technology and commitment to quality. The company, which was founded in {year}, has established itself as a trusted partner for businesses in a variety of sectors, including aerospace, medical, and automotive.One of the key factors that sets Swiss Turn apart from its competitors is its state-of-the-art facilities and cutting-edge equipment. The company's manufacturing plant is equipped with the latest CNC machines, allowing for the production of complex components with tight tolerances. In addition, Swiss Turn has a team of highly skilled engineers and technicians who are experts in their field and are dedicated to delivering excellence in every aspect of their work.In a recent interview, the CEO of Swiss Turn, {Name}, emphasized the company's commitment to staying ahead of the curve in terms of technology and innovation. "We understand the importance of investing in the latest equipment and continuously improving our processes to meet the evolving needs of our customers," {Name} said. "By staying at the forefront of technological advancements, we are able to offer our clients the highest-quality products and services."In addition to its focus on technology, Swiss Turn places a strong emphasis on quality control and assurance. The company has rigorous quality standards in place at every stage of the manufacturing process, from raw material inspection to final product testing. This commitment to quality has earned Swiss Turn a reputation for reliability and excellence among its customers.Furthermore, Swiss Turn prides itself on its ability to provide customized solutions to meet the unique needs of each client. The company works closely with its customers to understand their specific requirements and develop tailored manufacturing solutions that deliver optimal results. This customer-centric approach has allowed Swiss Turn to build long-lasting relationships with its clients and establish itself as a trusted partner in the industry.One of the most notable achievements of Swiss Turn is its success in the aerospace sector. The company has been a key supplier to several major aerospace companies, providing critical components that meet the stringent quality and performance standards required in the industry. Swiss Turn's expertise in producing complex aerospace components has made it a go-to partner for businesses operating in this sector.Looking ahead, Swiss Turn has ambitious plans for the future. The company is actively exploring opportunities to expand its presence in new markets and diversify its product offerings. In addition, Swiss Turn is committed to staying at the forefront of technology and innovation, with plans to invest in new equipment and capabilities to further enhance its manufacturing capabilities.In conclusion, Swiss Turn has solidified its position as a market leader in the manufacturing industry, thanks to its commitment to innovation, quality, and customer satisfaction. As the company continues to grow and expand, it is poised to further strengthen its reputation as a trusted partner for businesses seeking high-precision components. With its state-of-the-art facilities, skilled workforce, and customer-centric approach, Swiss Turn is well-equipped to meet the evolving needs of its clients and maintain its position at the forefront of the industry.

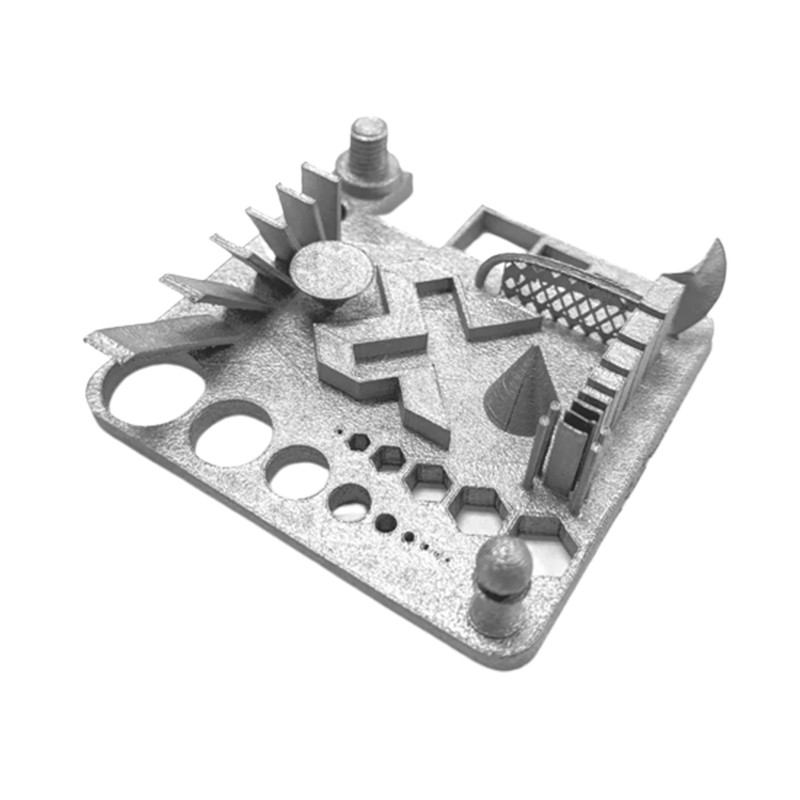

Top Quality 3D Printer Parts for Sale - Ultimate Guide

Recently, [Company Name], a leading manufacturer in the 3d printing industry, has announced the launch of a new line of 3d printer parts designed to enhance the capabilities and performance of their existing printers. This development comes as part of the company's ongoing commitment to innovation and providing their customers with the latest technology to meet their 3d printing needs.The new line of 3d printer parts includes a range of components such as extruders, hotends, and build platforms, all of which have been meticulously engineered to deliver superior precision and reliability. These parts are compatible with [Company Name]'s popular range of 3d printers, offering users the opportunity to upgrade their machines and achieve even better results.One of the key highlights of the new 3d printer parts is the advanced extruder design, which features a dual-drive gear system for improved filament grip and reliability. This innovative design ensures consistent extrusion and precise layering, resulting in high-quality 3d prints with fine details and smooth surfaces. Additionally, the hotends have been optimized for better heat dissipation and thermal stability, allowing for more consistent and uniform melting of filament materials.Furthermore, the new build platforms are constructed with high-quality materials to provide a sturdy and level printing surface. This is essential for ensuring the accuracy and stability of the printing process, ultimately leading to superior print quality and dimensional accuracy.In addition to the technical specifications, [Company Name] has also taken into account the ease of installation and maintenance when developing these new 3d printer parts. The components are designed to be user-friendly and hassle-free to install, allowing customers to quickly and conveniently upgrade their printers without the need for specialized technical knowledge.Speaking about the launch of the new 3d printer parts, [Company Name]'s CEO expressed his enthusiasm for the potential impact these components will have on the 3d printing community. "We are thrilled to introduce these new 3d printer parts, which have been meticulously engineered to push the boundaries of what our printers can achieve," he said. "These components will enable our customers to take their 3d printing capabilities to the next level, producing high-quality prints with greater ease and efficiency."The introduction of these new 3d printer parts further solidifies [Company Name]'s position as a pioneer in the 3d printing industry, consistently striving to provide cutting-edge solutions to its customers. With a strong focus on innovation and customer satisfaction, the company continues to push the boundaries of what is possible with 3d printing technology.In the coming months, [Company Name] plans to expand its range of 3d printer parts, with a continued emphasis on improving the performance, reliability, and user experience of its printers. This ongoing commitment to innovation and excellence reaffirms [Company Name]'s position as a leader in the 3d printing industry, and sets the stage for even more exciting developments in the future.

5 Innovative Prototyping Methods Shaping Manufacturing in China

Prototyping China Expands its Reach with Cutting-Edge ServicesIn today's fast-paced and ever-evolving world of technology and innovation, the importance of prototyping in product development cannot be overstated. Prototyping plays a crucial role in bringing new ideas to life and accelerating the production process, allowing companies to stay ahead of the competition. Recognizing the significance of prototyping in the manufacturing industry, Prototyping China has positioned itself as a leader in providing high-quality and efficient prototyping services.With a strong commitment to innovation and excellence, Prototyping China has expanded its reach and capabilities to meet the growing demand for advanced prototyping solutions. The company has leveraged its extensive experience and expertise to deliver cutting-edge services that cater to the diverse needs of its clients. From rapid prototyping to CNC machining, injection molding, and more, Prototyping China offers a comprehensive range of prototyping services that are tailored to each client's unique requirements.As a leading prototyping company, Prototyping China's core mission is to provide its clients with top-tier prototyping solutions that are tailored to their specific needs. The company prides itself on its ability to deliver high-precision prototypes with quick turnaround times, ensuring that clients can bring their products to market faster and more efficiently. With a focus on quality and customer satisfaction, Prototyping China has built a solid reputation for excellence in the prototyping industry.At the heart of Prototyping China's success is its state-of-the-art facility, which is equipped with the latest technology and machinery. The company's advanced prototyping capabilities enable it to produce prototypes with unparalleled precision and accuracy, setting it apart from its competitors. By investing in cutting-edge equipment and staying at the forefront of industry trends, Prototyping China remains at the forefront of the prototyping industry, consistently delivering superior results to its clients.Furthermore, Prototyping China's team of highly skilled engineers and technicians are dedicated to pushing the boundaries of prototyping and setting new standards for excellence. With their expertise and passion for innovation, the company's team ensures that each prototype meets the highest quality standards and exceeds client expectations. Whether it's a complex component or a simple prototype, Prototyping China has the capabilities and knowledge to bring any design to life with precision and efficiency.In addition to its technical prowess, Prototyping China places a strong emphasis on fostering strong and lasting relationships with its clients. The company works closely with each client to understand their unique prototyping needs and collaborate on developing solutions that align with their goals. Prototyping China's commitment to open communication and customer-centric approach has solidified its position as a trusted partner for prototyping services, earning the loyalty and trust of clients across the globe.Looking ahead, Prototyping China is poised to continue its expansion and further enhance its prototyping capabilities. The company remains dedicated to staying at the forefront of technological advancements and industry best practices, ensuring that it can continue to deliver the highest quality prototypes and exceed client expectations. With a focus on innovation, precision, and customer satisfaction, Prototyping China is well-positioned to lead the way in the ever-evolving world of prototyping.In conclusion, Prototyping China has solidified its position as a leader in providing top-tier prototyping solutions that cater to the diverse needs of its clients. With its commitment to excellence, cutting-edge capabilities, and customer-centric approach, Prototyping China continues to set new standards for the prototyping industry. As it expands its reach and enhances its capabilities, Prototyping China is poised to remain a trailblazer in the world of prototyping, offering unparalleled services to companies seeking to bring their innovative ideas to life.

Durable Sheet Metal Housings for Your Home: A Complete Guide

Sheet Metal Housings: The Perfect Solution for Your Industrial NeedsAs the demand for durable and reliable industrial enclosures continues to rise, it is important for businesses to invest in high-quality sheet metal housings. These housings are essential for protecting sensitive equipment and machinery from environmental factors and tampering, and are a critical component for many industrial applications.One company that has been at the forefront of providing top-notch sheet metal housings is {}. With a strong reputation for excellence and a commitment to delivering the highest quality products, {} has become a trusted name in the industry.{} has been in the business of manufacturing sheet metal housings for over two decades. Their extensive experience and expertise have enabled them to consistently produce enclosures that meet and exceed the needs of their diverse clientele. From small, custom enclosures to large-scale industrial solutions, {} has the capability to design and manufacture a wide range of sheet metal housings to suit any requirement.The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce sheet metal housings with precision and efficiency. Their team of skilled engineers and technicians work tirelessly to ensure that each housing meets the highest standards of quality and reliability. From the initial design phase to the final inspection process, {} is dedicated to delivering products that are built to last.One of the key advantages of {}'s sheet metal housings is their durability. Constructed from high-quality materials and built to withstand the harshest of environments, these enclosures provide superior protection for valuable equipment and machinery. Whether it's extreme temperatures, moisture, dust, or physical impact, {}'s sheet metal housings are designed to provide unparalleled defense against a wide range of threats.In addition to their resilience, {}'s sheet metal housings are also highly customizable. With the ability to fabricate enclosures in a variety of shapes, sizes, and configurations, the company can tailor their products to meet the specific needs of each customer. Whether it's a unique mounting requirement, specialized access points, or a custom finish, {} has the capability to create a housing that perfectly fits the intended application.Furthermore, {} places a strong emphasis on customer satisfaction. Their team of experts works closely with clients to understand their exact requirements and provide tailored solutions that meet and exceed expectations. From the initial consultation to the final delivery, {} is dedicated to providing a seamless and professional experience for their customers.From the manufacturing floor to the final installation, {} is committed to upholding the highest standards of quality and craftsmanship. With a rigorous quality control process in place, every sheet metal housing undergoes thorough testing to ensure that it meets the company's strict criteria for performance and reliability.With their unwavering dedication to excellence, {} is a company that businesses can trust to provide top-notch sheet metal housings for their industrial needs. As the demand for reliable and durable enclosures continues to grow, {} stands ready to meet the challenges of the industry and provide innovative solutions that set the standard for excellence.In conclusion, {}'s sheet metal housings are a testament to their commitment to quality, reliability, and customer satisfaction. With a track record of excellence and a strong reputation in the industry, {} is a company that businesses can rely on for all their sheet metal housing needs. As the industrial sector continues to evolve, {} remains at the forefront, delivering cutting-edge solutions that provide the highest level of protection for valuable equipment and machinery. When it comes to sheet metal housings, {} is the name that businesses can trust.

Maximizing Production with Injection Techniques: The Key to Efficiency

Production Injection, a leading provider of injection molding services, has recently announced the expansion of its production capabilities with the addition of a state-of-the-art facility. This expansion is a testament to the company's commitment to meeting the growing demand for high-quality injection molded products in various industries.With over [number] years of experience in the injection molding industry, Production Injection has established itself as a trusted partner for businesses looking to bring their product designs to life. The company's dedication to quality, precision, and efficiency has earned it a solid reputation in the market.The new facility, located in [location], features advanced injection molding machines and robotics, as well as a highly skilled team of engineers and technicians. This investment in cutting-edge technology and talent underscores Production Injection's determination to stay at the forefront of the industry and provide its clients with the best possible solutions."We are excited to announce the opening of our new facility, which will significantly expand our production capacity and capabilities," said [Spokesperson’s Name], CEO of Production Injection. "This expansion reflects our ongoing commitment to meeting the evolving needs of our customers and delivering exceptional results."The facility is equipped to handle a wide range of production requirements, from low-volume custom projects to high-volume mass production. With an emphasis on precision and consistency, Production Injection is well-positioned to serve industries such as automotive, consumer goods, electronics, medical devices, and more.In addition to its state-of-the-art equipment, Production Injection places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly practices throughout its operations, including the use of recyclable materials and energy-efficient production processes.Furthermore, Production Injection is dedicated to providing a safe and inclusive work environment for its employees. The company adheres to strict safety protocols and invests in ongoing training and development for its staff, ensuring that they are equipped to operate at the highest standards.As part of its commitment to continuous improvement, Production Injection also offers comprehensive design and engineering support to its clients. The company's team of experts works closely with customers to optimize their product designs for injection molding, offering valuable insights and recommendations to enhance manufacturability and cost-effectiveness."By partnering with Production Injection, businesses can benefit from our extensive knowledge and expertise in injection molding," said [Spokesperson’s Name]. "We are dedicated to providing comprehensive support throughout the entire production process, from initial concept to final product delivery."With the opening of its new facility, Production Injection is poised to strengthen its position as a leader in the injection molding industry and further solidify its reputation for excellence. The company's unwavering dedication to quality, innovation, and customer satisfaction sets it apart as a trusted partner for businesses seeking top-tier injection molding solutions.As Production Injection continues to grow and expand its capabilities, it remains committed to upholding the highest standards of performance and service. The company's investment in advanced technology, sustainable practices, and talent ensures that it will remain a driving force in the industry for years to come.

Discover the Benefits of 6-Axis Machining for Precision Manufacturing

The demand for precision and efficiency in the manufacturing industry continues to grow, and companies are constantly looking for innovative solutions to meet these needs. One such solution is the use of 6-axis machining technology. This cutting-edge technology allows for complex and intricate designs to be manufactured with unparalleled accuracy and speed.[Company Name] is at the forefront of this technological advancement, offering cutting-edge 6-axis machining services to their clients. With a strong focus on quality and innovation, they have established themselves as a leader in the industry.6-axis machining refers to the ability of a machine to move in six different directions, allowing for a much greater range of motion and flexibility compared to traditional 3-axis or 5-axis machines. This technology is particularly well-suited for the manufacturing of complex components, such as aerospace parts, medical devices, and automotive components.The advanced capabilities of 6-axis machining allow for the production of intricate and precise parts that would be nearly impossible to manufacture with traditional methods. This technology also offers significant time and cost savings, as it reduces the need for multiple setups and operations.[Company Name] has fully embraced this technology and has invested heavily in state-of-the-art 6-axis machining equipment. Their team of highly skilled engineers and technicians are able to take on the most demanding projects, delivering exceptional results for their clients.In addition to their advanced machining capabilities, [Company Name] also offers a wide range of value-added services, such as design assistance, material selection, and finishing processes. This comprehensive approach ensures that their clients receive exceptional support throughout the entire manufacturing process.With the increasing demand for precision components across a range of industries, the use of 6-axis machining technology is becoming more and more essential. This technology allows for the production of parts with extremely tight tolerances and complex geometries, making it an invaluable tool for manufacturers.[Company Name] has been able to leverage their expertise in 6-axis machining to serve a diverse range of industries, including aerospace, defense, medical, and automotive. Their commitment to quality and innovation has earned them a reputation as a trusted partner for companies looking to achieve the highest levels of precision and performance in their components.In an interview with [Company Name] CEO, they expressed their excitement about the future of 6-axis machining technology and its potential to revolutionize the manufacturing industry. They emphasized the company's dedication to staying at the forefront of technological advancements, continually investing in new equipment and training to ensure that they can continue to meet the evolving needs of their clients.As the manufacturing industry continues to evolve, the demand for precision and efficiency will only continue to grow. Companies like [Company Name] are leading the way in embracing new technologies such as 6-axis machining, providing their clients with the innovative solutions they need to stay ahead in today's competitive market.In conclusion, the use of 6-axis machining technology is revolutionizing the manufacturing industry, allowing for the production of highly complex and precise components with unprecedented efficiency. [Company Name] has established itself as a leader in this field, offering cutting-edge 6-axis machining services and supporting their clients with comprehensive engineering and design assistance. As the demand for precision components continues to grow, the importance of 6-axis machining technology will only continue to increase, and companies like [Company Name] will play a crucial role in meeting these evolving needs.

Guide to Injection Moldable Plastics: Benefits, Applications, and Best Practices

Injection Moldable Plastics (IMP) is a leading company in the plastic manufacturing industry, known for its high-quality and innovative products. Specializing in injection moldable plastics, the company has been a key player in providing solutions for a wide range of industries, including automotive, medical, consumer goods, and electronics.With a strong focus on research and development, IMP has continually pushed the boundaries of what is possible with injection moldable plastics. The company's team of experts is dedicated to creating new and improved materials that meet the ever-evolving needs of their customers.One of the key factors that set IMP apart from its competitors is the company's commitment to sustainable and environmentally friendly manufacturing practices. IMP has invested heavily in developing plastic materials that are recyclable and biodegradable, reducing the environmental impact of plastic waste.In addition to its commitment to sustainability, IMP is also dedicated to producing plastics that are safe and non-toxic. The company adheres to strict quality control measures to ensure that its products meet the highest safety standards, making them suitable for use in a wide range of applications, including food packaging and medical devices.Furthermore, IMP's dedication to innovation has led to the development of plastics with advanced properties, such as high tensile strength, heat resistance, and chemical resistance. These advanced materials have opened up new possibilities for product design and have allowed customers to create products with longer lifespan and improved performance.One of the key advantages of using injection moldable plastics from IMP is the flexibility they offer in product design and manufacturing. The company's materials can be molded into virtually any shape and size, allowing for complex and intricate designs that would not be possible with traditional materials. This versatility has made IMP's plastics a popular choice for companies looking to create unique and distinctive products.In recent news, IMP has announced the launch of a new line of injection moldable plastics that have been specifically designed for use in the automotive industry. These materials have been engineered to meet the rigorous demands of the automotive sector, including high impact resistance, temperature resistance, and long-term durability. With this new product line, IMP aims to further expand its presence in the automotive market and provide solutions for the industry's evolving needs.To ensure that its customers have access to the latest and most advanced plastic materials, IMP has also established strong partnerships with leading suppliers of raw materials and additives. These partnerships allow the company to stay at the forefront of material innovation and offer its customers the best possible solutions for their specific requirements.As part of its commitment to customer satisfaction, IMP provides comprehensive technical support and guidance to help its clients choose the right plastic materials for their applications. The company's team of experts is available to provide assistance with material selection, product design, and manufacturing processes, ensuring that customers can achieve the best results with IMP's plastics.Looking to the future, IMP is committed to continued innovation and the development of new and improved plastics that push the boundaries of what is possible in the industry. With a focus on sustainability, safety, and performance, the company aims to be a leading provider of injection moldable plastics for a wide range of applications, and to contribute to a more sustainable and environmentally friendly future.

- The Basics of Cnc Turning Centers and Their Uses

The world of manufacturing is constantly evolving with new technologies and innovations that aim to streamline processes and improve efficiency. One such technology that has been making waves in the manufacturing industry is the CNC Turning Center. These sophisticated machines have revolutionized the way precision components are produced and have become an integral part of modern manufacturing facilities.A CNC Turning Center is a machine tool that is used to create intricate and precise cylindrical components through the process of turning. This involves rotating a workpiece on a spindle while a cutting tool removes material to create the desired shape. What sets CNC Turning Centers apart from traditional turning machines is their ability to be programmed to run autonomously, resulting in higher accuracy and consistency in production.One of the leading suppliers of CNC Turning Centers is {Company Name}. With a strong focus on innovation and quality, {Company Name} has established itself as a trusted provider of advanced manufacturing solutions. Their range of CNC Turning Centers is known for its precision, reliability, and user-friendly interface, making them a popular choice among manufacturers across various industries.{Company Name}'s CNC Turning Centers are designed to handle a wide range of materials, including metals, plastics, and composites, making them versatile and adaptable to different manufacturing requirements. The machines are equipped with state-of-the-art control systems that allow for seamless integration with CAD/CAM software, enabling operators to create complex geometries with ease.In addition to their cutting-edge technology, {Company Name} takes pride in their commitment to customer satisfaction. Their team of highly skilled engineers and technicians provide comprehensive support services, including installation, training, and after-sales assistance, ensuring that customers are equipped with the knowledge and resources necessary to make the most out of their investment in CNC Turning Centers.Furthermore, {Company Name} is dedicated to continuous research and development, constantly refining and improving their CNC Turning Centers to meet the evolving needs of the manufacturing industry. Their relentless pursuit of excellence has earned them a reputation as a leader in the field of advanced manufacturing solutions.With the global manufacturing landscape becoming increasingly competitive, the demand for efficient and precise production technologies is greater than ever. CNC Turning Centers have emerged as a game-changer in this regard, offering manufacturers a powerful tool to drive productivity and maintain a competitive edge in the market. {Company Name} remains at the forefront of this technological revolution, offering cutting-edge CNC Turning Centers that are engineered to deliver exceptional performance and reliability.In conclusion, CNC Turning Centers have undoubtedly reshaped the way precision components are manufactured, and {Company Name} has played a pivotal role in driving this transformation. With their unwavering commitment to innovation, quality, and customer satisfaction, {Company Name} has positioned itself as a trusted partner for manufacturers seeking to leverage the power of CNC Turning Centers in their operations. As the manufacturing industry continues to evolve, it is certain that CNC Turning Centers will remain a cornerstone of modern production processes, and {Company Name} will continue to be a driving force in shaping this exciting future.

Cutting-Edge CNC Work: Latest Industry Updates and News

Work CNC, a leading provider of CNC systems and solutions, has recently announced the launch of their latest range of innovative CNC machines. The company has been at the forefront of the CNC industry for over 20 years, providing high-quality products and excellent customer service to a wide range of clients.The new range of CNC machines includes a variety of models designed for different applications, including milling, turning, grinding, and more. These machines are equipped with state-of-the-art technology and cutting-edge features to ensure precision, accuracy, and efficiency in every operation. With a focus on user-friendly interfaces and intuitive controls, these machines are suitable for both experienced operators and those new to CNC machining.Work CNC has a long-standing reputation for delivering reliable and durable CNC machines, and their latest range is no exception. These machines are built to withstand the demands of modern manufacturing environments, enabling businesses to increase productivity, reduce downtime, and produce high-quality parts with ease.In addition to their new range of CNC machines, Work CNC also offers a comprehensive range of services to support their clients. From installation and training to ongoing maintenance and technical support, the company is committed to ensuring that their customers get the most out of their CNC investment. With a team of highly skilled engineers and technicians, Work CNC provides expert advice and assistance to help businesses optimize their machining processes and achieve their production goals.The launch of this new range of CNC machines reflects Work CNC's dedication to innovation and continuous improvement. By investing in research and development, the company aims to stay ahead of market trends and provide cutting-edge solutions to meet the evolving needs of their customers. With a focus on quality, reliability, and performance, Work CNC is proud to offer a range of CNC machines that deliver exceptional value and long-term reliability."We are excited to introduce our latest range of CNC machines to the market," said a spokesperson for Work CNC. "These machines are the result of years of research, development, and refinement, and we are confident that they will meet the needs of businesses in a wide range of industries. Whether you are looking to increase productivity, improve accuracy, or reduce operating costs, our CNC machines provide the ideal solution."With a commitment to delivering innovative solutions and outstanding customer support, Work CNC continues to be a trusted partner for businesses seeking to enhance their machining capabilities. As the manufacturing industry evolves, the company remains dedicated to providing cutting-edge CNC systems and solutions that enable businesses to stay competitive and achieve their goals.As businesses around the world look to streamline their manufacturing processes and increase efficiency, Work CNC is well-positioned to meet their needs with their latest range of CNC machines. With a focus on quality, reliability, and performance, the company is a leader in the CNC industry and a valued partner for businesses seeking to optimize their production operations.

High-Quality CNC Plastic Parts for Various Applications

{Company Name}, a leading manufacturer of custom CNC plastic parts, has recently announced the launch of their new line of precision-machined plastic components. These advanced plastic parts are designed to meet the growing demand for high-quality, low-cost plastic components in various industries, including automotive, aerospace, medical, and consumer goods.With over 20 years of experience in the plastics industry, {Company Name} has developed a reputation for delivering top-notch CNC plastic parts that exceed customer expectations. By leveraging advanced CNC machining technology and a team of skilled engineers, the company is able to produce plastic parts with tight tolerances and exceptional surface finishes.The new line of precision-machined plastic components includes a wide range of products, such as gears, pulleys, housings, enclosures, and custom prototypes. These parts are available in a variety of plastic materials, including ABS, acrylic, polycarbonate, nylon, and PEEK, to meet the specific needs of different applications. Whether customers require small batches of custom plastic components or large production runs, {Company Name} is capable of delivering high-quality parts with fast turnaround times.One of the key advantages of {Company Name}'s CNC plastic parts is their ability to withstand harsh operating conditions, including high temperatures, corrosive chemicals, and mechanical stress. This makes them ideal for use in demanding applications, such as automotive engine components, aerospace interiors, medical devices, and industrial machinery.In addition to their exceptional performance characteristics, {Company Name}'s precision-machined plastic components are also cost-effective, offering significant savings compared to metal parts. This makes them an attractive option for businesses looking to reduce manufacturing costs without compromising on quality.{Company Name} takes pride in their commitment to quality and customer satisfaction. Their state-of-the-art manufacturing facility is equipped with the latest CNC machining centers, quality control equipment, and inspection tools to ensure that all plastic parts meet the highest standards of precision and consistency. Additionally, the company's team of engineers and production specialists works closely with customers to understand their unique requirements and provide tailored solutions to meet their needs."We are excited to introduce our new line of precision-machined plastic components to the market," said [Spokesperson's Name], the CEO of {Company Name}. "As a company that is dedicated to innovation and excellence, we are confident that these advanced plastic parts will empower our customers to achieve new levels of performance and efficiency in their products."With the launch of their new line of CNC plastic parts, {Company Name} aims to further strengthen its position as a leading provider of custom plastic components to industries worldwide. By offering a combination of superior quality, cost-effectiveness, and personalized service, the company is well-positioned to meet the evolving needs of the manufacturing market and drive innovation in the plastics industry.