Top Quality CNC Aluminum Products from China

By:Admin

Chinese CNC aluminum company has established itself as a leader in precision manufacturing, offering high-quality products and services to a wide range of industries. With a commitment to innovation and continuous improvement, the company has earned a reputation for excellence in the global market.

The company's state-of-the-art manufacturing facilities are equipped with the latest CNC technology, allowing for the production of complex and intricate aluminum components with the highest level of precision. Their team of highly skilled engineers and technicians work tirelessly to ensure that every product meets the stringent quality standards set by the company.

In addition to their cutting-edge manufacturing capabilities, the company also places a strong emphasis on research and development. They continuously invest in the latest technology and machinery, allowing them to stay ahead of the competition and offer their clients the most advanced solutions on the market.

With a focus on customer satisfaction, the company has built a strong reputation for reliability and dependability. Their commitment to meeting deadlines and delivering top-quality products has earned them the trust and loyalty of their clients.

Furthermore, the company takes pride in their environmental responsibility, implementing sustainable practices in their manufacturing processes. They strive to minimize waste and reduce their environmental footprint, ensuring that their operations are as eco-friendly as possible.

The company's dedication to excellence has not gone unnoticed. They have received numerous accolades and certifications, solidifying their position as a trusted industry leader. Their commitment to quality and innovation has positioned them as a preferred supplier for companies seeking top-quality aluminum components.

With a strong focus on the global market, the company has expanded its reach to serve clients around the world. Their products are in high demand across various industries, including aerospace, automotive, and electronics. Their ability to consistently meet the needs of their diverse client base has propelled them to the forefront of the industry.

In addition to their manufacturing prowess, the company's customer service is second to none. They pride themselves on building strong, long-lasting relationships with their clients, providing attentive support and guidance throughout every step of the production process. Their dedication to customer satisfaction sets them apart from the competition.

Looking to the future, the company remains committed to pushing the boundaries of precision manufacturing. They continue to invest in research and development, seeking new ways to enhance their production capabilities and expand their product offerings. With an unwavering commitment to excellence, they are well-positioned to maintain their status as a global leader in CNC aluminum manufacturing.

In conclusion, Chinese CNC aluminum company has established itself as a premier provider of precision-machined aluminum components. With a focus on quality, innovation, and customer satisfaction, they have earned the trust and loyalty of clients around the world. Their dedication to excellence and commitment to sustainability have positioned them as a leader in the industry, and their future looks brighter than ever as they continue to innovate and expand their capabilities.

Company News & Blog

High-quality 3D printed parts for aerospace and automotive industries

The emerging technology of 3D printing has revolutionized the manufacturing industry, allowing for highly complex and intricate parts to be produced with precision and efficiency. In recent years, the technology has expanded into the aerospace and automotive sectors, with companies such as {Company Name} leading the way in producing 3D printed parts for use in space exploration and high-performance vehicles.{Company Name} has been at the forefront of 3D printing innovation, pioneering the development of cutting-edge 3D printed parts for aerospace and automotive applications. The company's dedication to pushing the boundaries of what is possible with 3D printing has resulted in the creation of state-of-the-art components that have been used in a variety of high-profile projects.One of the key advancements made by {Company Name} is the use of SLS (Selective Laser Sintering) technology to produce high-strength, lightweight parts that are perfectly suited for use in the aerospace and automotive industries. SLS 3D printed parts have the ability to withstand extreme conditions and are capable of meeting the stringent performance requirements of these demanding sectors.The flexibility and versatility of SLS 3D printing allow for the production of complex geometries and intricate designs that would be impossible to achieve using traditional manufacturing methods. This has opened up new possibilities for the design and production of components that are lighter, stronger, and more efficient than ever before.{Company Name}'s expertise in SLS 3D printed parts has been put to the test in a number of high-profile projects, with the company consistently delivering solutions that meet and exceed the demands of its clients. Whether it's producing lightweight, high-strength components for use in space exploration or creating custom parts for high-performance vehicles, {Company Name} has consistently proven itself as a leader in the field of SLS 3D printing.The company's commitment to innovation and excellence has earned it a reputation as a trusted partner for companies in the aerospace and automotive industries. By leveraging the power of SLS 3D printing, {Company Name} has helped its clients achieve new levels of performance and efficiency, while also driving down production costs and lead times.As the demand for high-performance, lightweight components continues to grow, {Company Name} remains dedicated to pushing the boundaries of what is possible with SLS 3D printing. The company's ongoing investment in research and development ensures that it stays at the forefront of the industry, leading the way in the creation of innovative solutions that continue to redefine what is possible in aerospace and automotive manufacturing.In conclusion, the use of SLS 3D printed parts by {Company Name} is revolutionizing the aerospace and automotive industries, allowing for the creation of high-strength, lightweight components that are perfectly suited for use in these demanding sectors. With its dedication to innovation and excellence, {Company Name} continues to lead the way in pushing the boundaries of what is possible with 3D printing, providing its clients with the cutting-edge solutions they need to succeed in today's fast-paced and competitive marketplace.

Top Suppliers for CNC Machine Parts - Find Quality Parts Here

CNC Machine Parts Suppliers, a leading supplier of high-quality CNC machine parts, is proud to announce the addition of a new line of products to their inventory. With a dedication to providing top-of-the-line components for manufacturing and industrial needs, CNC Machine Parts Suppliers continues to expand their offerings to meet the growing demands of their customers.The company, founded in 2005, has quickly established itself as a trusted source for CNC machine parts, with a focus on delivering reliable and durable products to clients across various industries. Their commitment to quality and customer satisfaction has earned them a reputation as a go-to supplier for precision components in the manufacturing sector.As CNC machining continues to play a crucial role in the production of various goods, the need for high-quality machine parts has become increasingly evident. CNC Machine Parts Suppliers recognized this demand and has since made it their mission to provide a comprehensive range of components for CNC machines, including but not limited to tool holders, spindle motors, and cutting tools.The new line of products that CNC Machine Parts Suppliers has introduced includes a variety of cutting-edge components designed to enhance the efficiency and performance of CNC machines. This expansion of their inventory demonstrates the company's commitment to staying at the forefront of technological advancements in the industry, as they continuously strive to offer the latest and most innovative products to their customers.In addition to their extensive range of products, CNC Machine Parts Suppliers also prides itself on offering exceptional customer service and technical support. Their team of knowledgeable professionals is readily available to assist clients with finding the right parts for their specific needs, as well as providing guidance on installation and maintenance to ensure optimal functionality of the components.With a customer-centric approach, CNC Machine Parts Suppliers has built strong and lasting relationships with a wide network of clients, including small businesses, large corporations, and OEM manufacturers. The company's dedication to delivering reliable and cost-effective solutions has earned them the trust and loyalty of their customers, making them a preferred supplier in the CNC machining industry.CNC Machine Parts Suppliers remains committed to upholding the highest standards of quality in all their products, with a rigorous quality control process in place to ensure that every component meets the strict specifications and requirements of their clients. This unwavering commitment to excellence has been a driving force behind the company's success and continued growth in the industry.As the demand for precision CNC machine parts continues to rise, CNC Machine Parts Suppliers is well-positioned to meet the needs of their customers with their expanded product line and unwavering dedication to quality and customer satisfaction. With a solid reputation for reliability and a proven track record of delivering top-notch components, the company stands out as a leading supplier in the CNC machining industry.In conclusion, CNC Machine Parts Suppliers' expansion of their product line is a testament to their ongoing commitment to providing cutting-edge solutions for the manufacturing and industrial sectors. With a focus on quality, innovation, and customer satisfaction, the company is well-equipped to meet the evolving needs of their clients and to continue making a significant impact in the CNC machining industry.

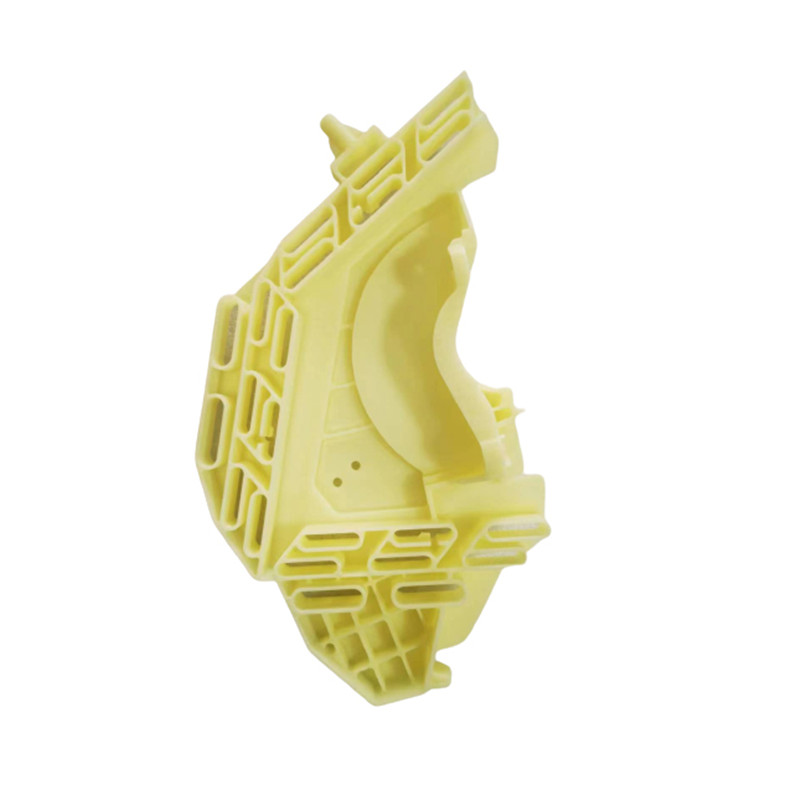

High-Quality Injection Molding Machine Mold for Efficient Production

Injection Molding Machine Mold Technology Provides Precision and EfficiencyInjection molding is a widely used manufacturing process for producing parts by injecting material into a mold. With the advancement of technology, injection molding machines and molds have become more sophisticated and efficient. One company at the forefront of this technology is {}.{} is a leading provider of injection molding machine molds in the industry. With years of experience and expertise in the field, they have become known for their precision and high-quality molds. The company's dedication to innovation has led them to develop advanced technologies that provide their customers with the best-in-class molding solutions.The injection molding machine mold technology offered by {} is designed to provide superior precision and efficiency. Their molds are engineered using the latest software and manufacturing processes, ensuring that the final product meets the highest standards of quality. With a strong focus on innovation and continuous improvement, {} is able to deliver molds that are not only precise but also highly efficient, ultimately enabling their customers to achieve optimal results in their manufacturing processes.One of the key features of {}'s injection molding machine molds is their ability to produce complex and intricate parts with ease. The molds are designed to have high levels of accuracy and consistency, allowing for the production of parts with tight tolerances and intricate details. This level of precision is crucial in various industries, including automotive, medical, and consumer goods, where the quality and functionality of the parts are paramount.In addition to precision, {}'s molds are also known for their efficiency. The company has incorporated innovative features into their molds to optimize the injection molding process, resulting in reduced cycle times and increased productivity. By streamlining the manufacturing process, {}'s molds help their customers save time and resources, ultimately improving their overall operational efficiency.Another notable aspect of {}'s injection molding machine molds is their versatility. The company offers a wide range of mold solutions that can accommodate various materials, sizes, and complexities. Whether it's simple components or intricate parts, {} has the expertise and capabilities to deliver molds that meet the unique requirements of their diverse customer base.As a company, {} is committed to providing exceptional customer service and support. Their team of experts works closely with customers to understand their specific needs and provide tailored solutions that address their manufacturing challenges. From the initial design phase to the final production, {} is dedicated to ensuring that their customers' expectations are not just met, but exceeded.In conclusion, {} is a pioneering force in the injection molding industry, offering cutting-edge machine molds that provide precision, efficiency, and versatility. Their relentless commitment to innovation and customer satisfaction has established them as a trusted partner for manufacturers seeking high-quality molding solutions. With {}'s injection molding machine molds, customers can expect nothing less than exceptional performance and superior results in their manufacturing processes.

Rapid Prototype Machine Shop: What You Need to Know about Rapid Prototyping Services

Rapid Prototype Machine Shop, a leading innovator in the field of additive manufacturing, is revolutionizing the way prototypes are created and manufactured. This groundbreaking company provides cutting-edge solutions for businesses, helping them to streamline their product development process and reduce time to market.Founded in [year], Rapid Prototype Machine Shop has quickly made a name for itself in the industry, with a strong focus on delivering high-quality prototypes and production runs for a wide range of industries, including aerospace, automotive, medical, and consumer products.The company's state-of-the-art facility is equipped with the latest in 3D printing and additive manufacturing technology, allowing them to produce prototypes and end-use parts with unprecedented speed and precision. Their team of highly skilled engineers and technicians are dedicated to providing superior service and support to their clients, ensuring that every project is completed with the utmost attention to detail and quality.One of the key differentiators for Rapid Prototype Machine Shop is their commitment to continuous innovation and investment in the latest technology. This has allowed them to stay ahead of the curve and offer their clients the most advanced solutions for their prototyping and manufacturing needs.In addition to their cutting-edge technology, the company offers a wide range of materials for their 3D printing services, including various metals, plastics, and composite materials. This flexibility enables their clients to create prototypes and end-use parts that meet the specific requirements of their applications, whether it be for functional testing, product validation, or final production.Rapid Prototype Machine Shop's dedication to quality and excellence has earned them a reputation as a trusted partner for businesses looking to bring their products to market faster and more efficiently. Their track record of success and customer satisfaction speaks for itself, with countless success stories from clients who have leveraged their services to gain a competitive edge in their respective industries.Furthermore, the company's commitment to sustainability and environmental responsibility sets them apart from their competitors. They prioritize the use of eco-friendly materials and processes wherever possible, ensuring that their manufacturing practices have minimal impact on the environment. This aligns with their mission to not only deliver exceptional results for their clients, but to do so in a way that is mindful of the planet and future generations.Looking ahead, Rapid Prototype Machine Shop is poised for continued growth and success as they expand their capabilities and reach new markets. With an unwavering dedication to innovation, quality, and customer satisfaction, they are well-positioned to remain at the forefront of the additive manufacturing industry for years to come.In conclusion, Rapid Prototype Machine Shop has established itself as a leader in the field of additive manufacturing, providing best-in-class solutions for businesses seeking to accelerate their product development process. With a focus on innovation, quality, and sustainability, the company is well-equipped to meet the evolving needs of its clients and drive further advancements in the industry. Whether it's the aerospace, automotive, medical, or consumer products sector, Rapid Prototype Machine Shop is the go-to partner for businesses looking to bring their ideas to life with speed and precision.

Revolutionizing Healthcare: The Impact of 3D Printing in Medical Parts Production

3D printing technology has made significant advances in recent years, and it's now being used in the medical field to produce vital medical parts. {}. The company is at the forefront of this innovative technology, utilizing 3D printing to create essential medical components for various healthcare applications.With the rapid advancement of 3D printing technology, the medical industry has been exploring new ways to incorporate this cutting-edge process into its practices. 3D printing allows for the creation of complex, intricate parts that are difficult to manufacture using traditional methods. This technology has the potential to revolutionize the way medical devices and components are produced, offering more customization and precision than ever before.{}. is leading the way in leveraging 3D printing to produce medical parts that are used in a variety of medical devices and equipment. By utilizing advanced 3D printing techniques and materials, the company is able to create high-quality, intricate components that meet the strict regulatory standards of the medical industry.One of the key benefits of using 3D printing for medical parts is the ability to produce customized components tailored to the specific needs of each patient. This level of customization is particularly important in the medical field, where one-size-fits-all solutions are often inadequate. With 3D printing, medical parts can be designed and manufactured to fit the unique anatomy of individual patients, resulting in better outcomes and improved patient care.In addition to customization, 3D printing also offers faster production times and reduced costs compared to traditional manufacturing methods. This means that medical facilities can access critical components more quickly and affordably, ultimately improving patient care and reducing overall healthcare expenses.The potential applications of 3D printing in the medical field are vast. From creating patient-specific implants and prosthetics to manufacturing intricate surgical tools and instrument components, 3D printing has the potential to transform the way medical devices and equipment are produced.{}. is at the forefront of this technological revolution, offering a wide range of 3D printed medical parts that are used in various healthcare settings. The company's expertise in 3D printing and its commitment to quality and innovation have positioned it as a trusted partner for medical device manufacturers and healthcare providers around the world.As the demand for customized, high-quality medical components continues to grow, the role of 3D printing in the medical field is becoming increasingly vital. {}. is dedicated to staying at the forefront of this evolving industry, continuously investing in new technologies and processes to deliver cutting-edge 3D printed medical parts that meet the ever-changing needs of the healthcare sector.The ongoing advancements in 3D printing technology are opening up new possibilities for the medical field, and companies like {} are leading the way in leveraging this technology to improve patient care and advance the capabilities of medical devices and equipment. With its expertise and dedication to innovation, {}. is well-positioned to continue driving the adoption of 3D printing in the medical industry and shaping the future of healthcare.

Reliable and Expert 3D Printing Services for SLS Technology

Sla 3d Printing Services (need remove brand name) debuts new high-speed 3D printing serviceSla 3d Printing Services (need remove brand name) is pleased to announce the launch of its latest high-speed 3D printing service, which offers unparalleled speed and efficiency for rapid prototyping and small-batch production. This cutting-edge technology allows for faster turnaround times and higher-quality prints, making it an ideal solution for businesses looking to bring their designs to life quickly and cost-effectively.With the addition of this new service, Sla 3d Printing Services (need remove brand name) continues to solidify its position as a leader in the 3D printing industry. The company has built a strong reputation for providing top-of-the-line 3D printing solutions to a wide range of clients, from small startups to large corporations. Its commitment to innovation and customer satisfaction has made it a trusted partner for businesses looking to leverage the power of 3D printing."We are thrilled to offer this new high-speed 3D printing service to our clients," said [Company Spokesperson]. "With this technology, we can deliver exceptional quality prints at an unprecedented pace, allowing our clients to bring their products to market faster than ever before. Whether they need rapid prototyping or small-batch production, this service is designed to meet their needs and exceed their expectations."The high-speed 3D printing service utilizes state-of-the-art SLA (stereolithography) technology to achieve incredibly fast print speeds without sacrificing print quality. This technology allows for the creation of intricate and precise parts with smooth surface finishes, making it an ideal solution for a wide range of applications, including engineering, product design, and manufacturing.In addition to its speed and precision, the new service offers a high degree of versatility, allowing clients to choose from a variety of materials to meet their specific needs. Whether they require rigid, flexible, or transparent parts, Sla 3d Printing Services (need remove brand name) can deliver the perfect solution for their project.To complement its cutting-edge technology, Sla 3d Printing Services (need remove brand name) maintains a team of highly skilled engineers and technicians who are dedicated to ensuring the success of every project. From assisting with design optimization to providing expert guidance on material selection, the company's team of professionals is committed to delivering exceptional results for its clients.As part of its commitment to customer satisfaction, Sla 3d Printing Services (need remove brand name) also offers comprehensive post-processing and finishing services to ensure that every part meets the highest standards of quality. From painting and coating to surface smoothing and assembly, the company can provide a complete end-to-end solution for its clients, saving them time and resources in the production process.With the launch of its new high-speed 3D printing service, Sla 3d Printing Services (need remove brand name) is poised to continue its upward trajectory in the 3D printing industry. By leveraging the latest technology and a strong focus on customer service, the company is well-positioned to meet the evolving needs of businesses seeking innovative 3D printing solutions.About Sla 3d Printing Services (need remove brand name):Sla 3d Printing Services (need remove brand name) is a leading provider of 3D printing services, offering a wide range of solutions for rapid prototyping and small-batch production. With a strong commitment to innovation and customer satisfaction, the company has established itself as a trusted partner for businesses looking to harness the power of 3D printing. Its team of skilled professionals and state-of-the-art technology enable it to deliver exceptional results for a diverse range of clients.For more information about Sla 3d Printing Services (need remove brand name) and its new high-speed 3D printing service, please visit [company website].

Affordable CNC Machining Services for Your Business

Cheap CNC Machining Solutions Making Manufacturing More Accessible for Small BusinessesIn today's competitive manufacturing industry, small businesses are often at a disadvantage when it comes to accessing cost-effective manufacturing solutions. However, with the advancement of technology and the rise of affordable CNC machining services, small businesses now have the opportunity to compete on a level playing field with larger companies.One company that is leading the charge in providing cheap CNC machining solutions is {Company Name}. Established in 2005, {Company Name} is a leading provider of precision CNC machining services for a wide range of industries, including aerospace, automotive, medical, and electronics. With their state-of-the-art facilities and a team of highly skilled engineers and machinists, {Company Name} has built a reputation for delivering high-quality machining solutions at competitive prices.The key to {Company Name}'s success lies in their ability to leverage the latest CNC machining technology to streamline their production processes and reduce manufacturing costs. By utilizing advanced CNC machines and automation technology, {Company Name} is able to minimize manual labor and maximize efficiency, resulting in lower production costs and faster turnaround times for their clients.One of the main advantages of {Company Name}'s cheap CNC machining solutions is their ability to accommodate small batch production runs. Unlike traditional manufacturing methods that require expensive tooling and setup costs, {Company Name}'s CNC machining services are ideal for producing small quantities of parts and components at a fraction of the cost. This is particularly beneficial for small businesses that may not have the resources to invest in large-scale production runs but still require high-quality machined parts for their products.Another key aspect of {Company Name}'s cheap CNC machining solutions is their commitment to quality and precision. With a strict quality control process in place, {Company Name} ensures that all machined parts meet the highest standards of accuracy and consistency. This level of precision is essential for industries such as aerospace and medical, where the performance and reliability of machined components are critical.In addition to their affordable pricing and quality assurance, {Company Name} also provides comprehensive engineering support to help clients optimize their designs for CNC machining. Their team of experienced engineers works closely with clients to analyze their designs, identify potential improvements, and offer valuable insights to enhance the manufacturability and cost-effectiveness of their parts.As a result of {Company Name}'s cheap CNC machining solutions, small businesses are now able to bring their innovative ideas to life without breaking the bank. By outsourcing their machining needs to {Company Name}, small businesses can benefit from the cost savings, fast turnaround times, and expertise of a trusted manufacturing partner, allowing them to focus on growing their business and driving innovation.With the increasing demand for affordable manufacturing solutions, {Company Name} is perfectly positioned to continue supporting small businesses and entrepreneurs in bringing their products to market. As technology continues to advance and CNC machining becomes more accessible, the future looks bright for small businesses looking to compete in the global manufacturing landscape.

Advanced CNC Swiss Machining Services for Precision Engineering

CNC Swiss Machining, also known as Swiss style machining, is a highly precise and efficient manufacturing process that has become increasingly popular in the production of small, complex parts. This machining process is especially well-suited for the production of components that require tight tolerances, intricate geometries, and high precision.The CNC Swiss Machining process utilizes a rotating cutting tool to remove material from a workpiece that is held in place by a guide bushing. This allows for extremely precise and accurate machining, making it ideal for the production of parts for industries such as aerospace, medical, automotive, and electronics.One of the leading companies in the CNC Swiss Machining industry is {}. With over 20 years of experience, they have established themselves as a trusted and reliable provider of high-quality precision machining services. Their state-of-the-art facility is equipped with the latest CNC Swiss machining technology, allowing them to produce complex parts with unparalleled accuracy and efficiency.The company's team of highly skilled machinists and engineers are dedicated to delivering exceptional quality and precision in every project they undertake. Whether it's a small batch of prototype parts or a large-scale production run, {} has the expertise and capability to meet the diverse needs of their customers.{}'s commitment to innovation and continuous improvement is evident in their investment in the latest CNC Swiss machining equipment and technologies. This allows them to stay ahead of the curve and consistently deliver superior quality parts that meet the strictest industry standards.In addition to their cutting-edge machining capabilities, {} also offers a range of value-added services such as design assistance, prototyping, and precision assembly. This comprehensive approach allows them to provide end-to-end solutions to their customers, ensuring a seamless and efficient manufacturing process from start to finish.As a customer-focused company, {} places a strong emphasis on building long-term partnerships with their clients. They pride themselves on their responsiveness, flexibility, and ability to adapt to the unique needs of each customer. This approach has earned them a reputation for reliability and excellence in the industry.With a strong commitment to quality, precision, and customer satisfaction, {} is well-positioned to continue leading the way in the CNC Swiss machining industry. Their dedication to excellence, paired with their advanced capabilities and comprehensive services, makes them the go-to partner for companies looking to produce high-quality, complex parts with utmost precision and efficiency.As the demand for small, complex parts continues to grow across various industries, the importance of CNC Swiss machining in the manufacturing sector cannot be overstated. With its ability to produce parts with exceptional accuracy and tight tolerances, it is a crucial technology that enables companies to meet the evolving needs of the market.In conclusion, CNC Swiss machining is a vital manufacturing process that plays a key role in the production of small, intricate parts. With leading companies like {} at the forefront of the industry, the future of CNC Swiss machining looks promising, as it continues to drive innovation, precision, and excellence in the manufacturing sector.

3D printed prototypes revolutionize SLS technology

In recent years, 3D printing technology has rapidly advanced, paving the way for innovative and more efficient production processes. One company at the forefront of this revolution is {}, a leading provider of cutting-edge 3D printing solutions. With their state-of-the-art selective laser sintering (SLS) technology, they are able to produce high-quality prototypes and end-use parts with unmatched precision and speed. {}'s SLS 3D printing process involves using a high-powered laser to selectively fuse powdered materials, such as plastics, nylon, or metals, layer by layer to create the desired object. This method allows for the production of complex and intricate designs that would be difficult or impossible to achieve using traditional manufacturing methods. The resulting prototypes and parts are durable, high-performance, and fully functional, making them ideal for a wide range of applications across industries.In addition to the technical prowess of their SLS 3D printing technology, {} offers a comprehensive suite of services to support their clients throughout the entire production process. From design and engineering support to post-processing and finishing, they work closely with their customers to ensure that their unique requirements are met with precision and expertise. This holistic approach sets {} apart as a trusted partner for companies looking to leverage the power of 3D printing for their prototyping and production needs.One of the key advantages of {}'s SLS 3D printing technology is its ability to rapidly produce prototypes and end-use parts with minimal lead times. Traditional manufacturing methods often involve lengthy setup and tooling processes, which can result in extended production timelines and increased costs. With SLS 3D printing, {} is able to bypass these constraints and deliver quick turnarounds without compromising on quality or performance. This agility is especially valuable for companies operating in fast-paced and competitive markets, where speed to market is a crucial factor in achieving success.Furthermore, {}'s SLS 3D printed prototypes and parts are highly customizable, allowing for design iterations and modifications to be made with ease. This flexibility is invaluable for companies seeking to refine and optimize their products before committing to mass production. By leveraging {}'s advanced 3D printing capabilities, they can quickly test and validate their designs, resulting in higher quality end products and reduced development costs.In recent years, {}'s SLS 3D printing technology has been instrumental in driving innovation across a diverse range of industries, including aerospace, automotive, medical, and consumer goods. Their ability to produce lightweight yet robust parts with complex geometries has unlocked new possibilities for product design and performance, leading to breakthroughs in efficiency and functionality. As a result, {} has earned a reputation as a trusted partner for companies looking to push the boundaries of what is possible with 3D printing.Looking ahead, {} is committed to furthering the capabilities of their SLS 3D printing technology, with ongoing investments in research and development. By continuously refining their materials, processes, and systems, they aim to empower their clients with even greater freedom and flexibility in their product development and manufacturing efforts. As the demand for advanced 3D printing solutions continues to grow, {} is poised to lead the way with their unparalleled expertise and cutting-edge technologies.In conclusion, {}'s SLS 3D printed prototypes and parts represent a paradigm shift in the world of manufacturing, offering companies a powerful tool to drive innovation and achieve new levels of efficiency. With their unwavering commitment to excellence and customer satisfaction, {} has established themselves as a true leader in the 3D printing industry, poised to shape the future of production for years to come.

High-Quality Precision Turned Parts for CNC Machining Services

CNC Precision Turned Parts (Branded Removed) - Setting New Standards in Precision ManufacturingIn today’s fast-paced industrial world, precision is key. The demand for high-quality, precision-engineered components is ever-increasing, and companies are constantly seeking out reliable and efficient solutions to meet these demands. One such company that is making waves in the industry is [Company Name], a leading provider of CNC precision turned parts.[Company Name] has been at the forefront of precision manufacturing for over [X] years, and their commitment to excellence has earned them a reputation for delivering top-notch products to a wide range of industries, including automotive, aerospace, electronics, and more. Their dedication to quality and continuous improvement has allowed them to stay ahead of the competition and remain a trusted partner for businesses looking for precision-engineered components.The company’s state-of-the-art facility is equipped with the latest CNC technology, allowing them to produce complex turned parts with the highest level of accuracy and precision. This technology, combined with their team of skilled engineers and technicians, enables [Company Name] to consistently deliver components that meet the tightest tolerances and specifications.One of the key factors that set [Company Name] apart from their competitors is their ability to provide custom solutions to their clients. They understand that every project is unique and may require specialized components, which is why they work closely with their clients to develop custom solutions that meet their specific needs. Whether it’s a small batch of prototypes or a large-scale production run, [Company Name] has the capabilities to deliver high-quality turned parts that exceed expectations.In addition to their CNC precision turned parts, [Company Name] also offers a range of value-added services, such as heat treating, plating, and assembly, providing their clients with a one-stop solution for all their precision component needs. This comprehensive approach allows for a seamless and efficient manufacturing process, saving time and resources for their clients.Furthermore, [Company Name] places a strong emphasis on quality control and inspection processes to ensure that every part that leaves their facility meets the highest standards. Their commitment to quality is reflected in their ISO 9001 certification, demonstrating their dedication to maintaining rigorous quality management systems.The team at [Company Name] understands the importance of staying ahead of the curve in terms of technology and innovation. They are constantly investing in new equipment and techniques to enhance their manufacturing capabilities and keep up with the ever-evolving needs of the industry. This forward-thinking approach has allowed [Company Name] to stay at the forefront of precision manufacturing and continue to push the boundaries of what is possible in the field.As the demand for precision-engineered components continues to grow, [Company Name] is well-positioned to meet these demands and serve as a reliable partner to businesses across a wide range of industries. Their dedication to excellence, commitment to quality, and ability to provide custom solutions set them apart as a leader in the field of CNC precision turned parts.In conclusion, [Company Name] has established itself as a leading provider of CNC precision turned parts, setting new standards in the industry with their commitment to excellence, custom solutions, and continuous improvement. With their state-of-the-art facility, skilled team, and comprehensive approach, they are well-equipped to meet the evolving needs of the industry and continue to deliver high-quality precision-engineered components to their clients.