- Home

- Sintering In 3d Printing

Sintering in 3D Printing: Top Manufacturer for Wholesale Supply

Introducing our latest innovation in 3D printing technology – Sintering in 3D Printing. Our company, Guangdong Shunde Teamwork Model Co., Ltd., is excited to offer this cutting-edge manufacturing method that is revolutionizing the industry. Sintering in 3D Printing involves using high-powered lasers to fuse small particles of material together, creating solid and intricate 3D objects. This process allows for excellent precision and intricate detailing, making it perfect for creating complex and durable products. As a leading manufacturer, supplier, and factory in China, we are dedicated to providing top-quality 3D printing solutions to meet all your needs. With Sintering in 3D Printing, the possibilities are endless – from rapid prototyping to mass production of custom components. Experience the future of manufacturing with our advanced Sintering in 3D Printing technology. Trust Guangdong Shunde Teamwork Model Co., Ltd. to bring your designs to life with the highest quality and unparalleled expertise.

Guangdong Shunde Teamwork Model Technology Co., Ltd.

Company News

Related News

Customized precision component metal machining parts CNC aluminium part service

Custom Precision Metal Machining Parts - CNC Aluminium Part Service. We are a factory specializing in providing customized metal machining solutions for precision components.

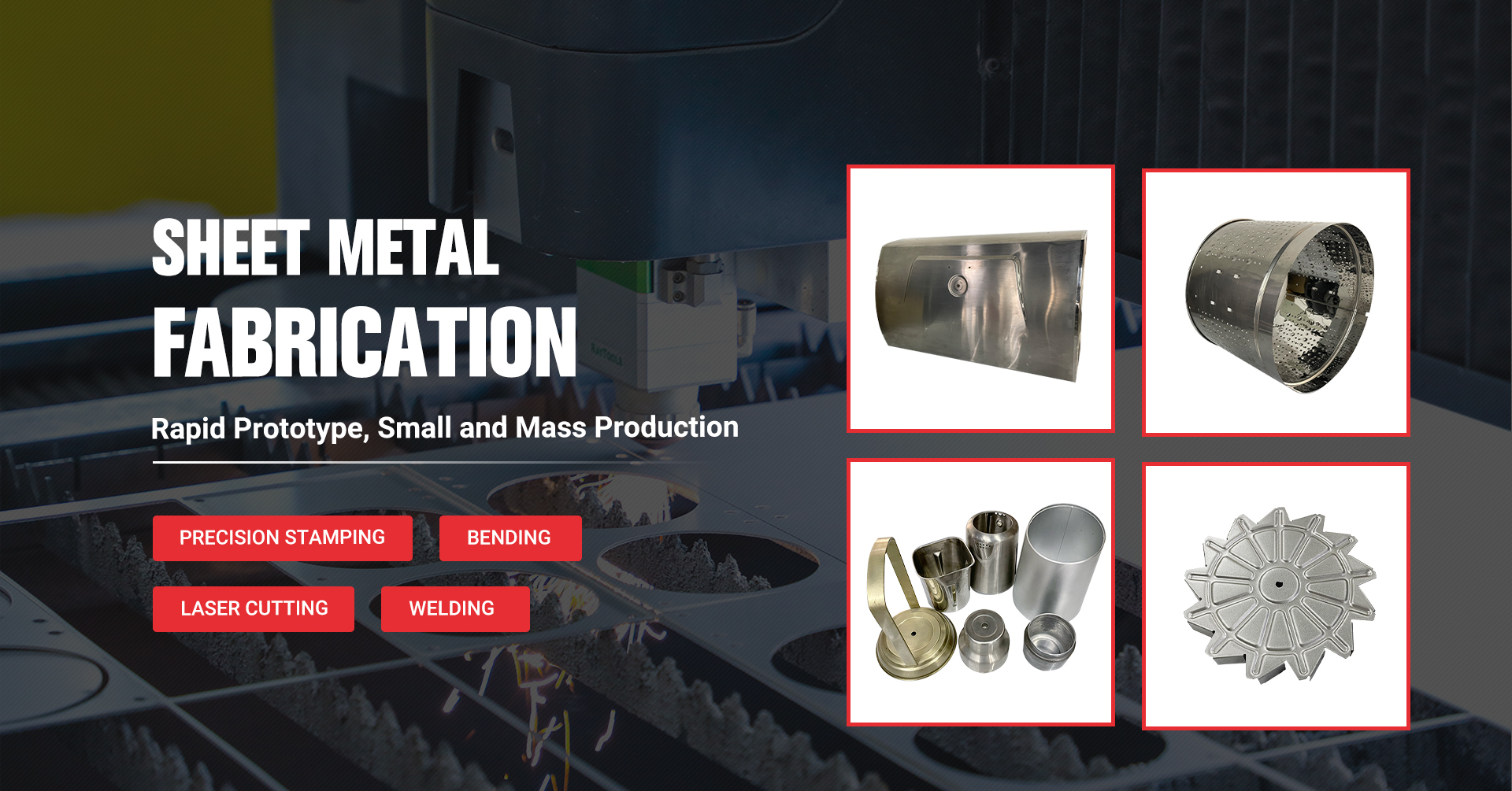

Sheet metal fabrication metal stamping manufacturer

PrecisionMakers - your premier choice for sheet metal fabrication and metal stamping. As a factory, we deliver top-quality products at competitive prices.

OEM CNC Machining Parts Stainless Steel Turning Miling Parts

Shop for high-quality OEM CNC Machining Parts Stainless Steel Turning Milling Parts at our factory. Precision manufacturing for your custom needs.

Customized high-quality 3D printing plastic service Chinese prototype factory

Welcome to our Chinese prototype factory, specializing in customized high-quality 3D printing plastic services. Get in touch for top-notch prototypes.

Custom precision CNC machining brass part service manufacturer

Get the best precision CNC machined brass parts from our factory. Customized service for your specific needs. Contact us now for a quote!

Custom precision CNC machining brass part service manufacturer

Get custom precision CNC machining brass parts from our factory. We are a leading manufacturer with expertise in producing high-quality components.

Custom Black ABS Resin CNC Machining Parts Plastic Prototypes

Get high-quality Custom Black ABS Resin CNC Machining Parts Plastic Prototypes from our factory. Precision engineered for your specific needs.

Custom precision rapid prototype ABS plastic 3D printing parts services

Precision ABS Plastic Prototypes | Factory Direct 3D Printing - Get custom rapid parts with fast turnaround times. Contact our experienced team today!

Custom automotive sheet metal/metal prototype parts

Custom Automotive Metal Works - Quality prototype parts made at our factory. Specializing in sheet metal fabrication for automotive applications.

Customized metal parts stainless steel part stretching&spinning factory OEM service

Stainless Steel Stretching & Spinning Factory - Custom OEM Service - High Quality Metal Parts - Competitive Prices - Fast Turnaround Time. Contact Us Today!

OEM High Performance 3D Printing Metal Parts Prototype Chinese Supplier

Get high-quality OEM high performance 3D printing metal parts prototype from Chinese supplier. We offer factory-direct pricing and exceptional quality.

OEM cnc sheet metal bending laser cutting service manufacturer

Discover precision metal fabrication services from our OEM CNC sheet metal bending and laser cutting factory. Get custom solutions for your needs.

OEM CNC Aluminum Precision Machining Components

OEM CNC Aluminum Precision Machining Components - We are a factory specializing in high-quality aluminum machining components. Contact us today!

New High Preformance 3D Printing SLS PLA Nylon Model Sample Prototype

Get the best quality 3D printing samples for your prototypes from our factory. Our new high-performance SLS PLA Nylon models are perfect for testing and showcasing your designs.

OEM component metal machining parts CNC aluminium factory service

OEM Component Metal Machining Parts - High-quality CNC aluminium products manufactured in our factory. Get custom parts for your needs.

- Sintering In 3D Printing: The Ultimate Guide for Manufacturers

- Reviews

- Related Videos

Introducing our latest innovation in 3D printing technology - Sintering in 3D Printing. Our cutting-edge 3D printer utilizes sintering technology to create precise and durable 3D printed objects with impeccable detail and strength. This advanced method involves using a high-powered laser to selectively fuse powdered materials together, layer by layer, resulting in high-quality, fully functional parts. Sintering in 3D Printing offers numerous advantages over traditional 3D printing methods. The sintering process allows for the use of a wide range of materials, including metals, ceramics, and polymers, making it ideal for a variety of industrial applications. Additionally, our sintering 3D printer can produce complex geometries and intricate designs with ease, providing limitless possibilities for designers and engineers. Whether you are in the aerospace, automotive, medical, or consumer goods industries, our Sintering in 3D Printing technology can revolutionize your manufacturing process. With its precise, high-quality output, our 3D printer can help streamline production, reduce costs, and accelerate innovation. Experience the future of additive manufacturing with our Sintering in 3D Printing technology. Unlock new possibilities for your business and stay ahead of the competition with our state-of-the-art 3D printing solution. Contact us today to learn more about how our sintering technology can elevate your manufacturing capabilities.

I recently had the opportunity to try out a 3D printing machine with sintering technology and I was blown away by the results. The sintering process fuses powdered materials together to create incredibly precise and durable 3D printed objects. The level of detail and strength of the finished products is truly impressive. Plus, the sintering technology allows for a wide range of materials to be used, from metals to ceramics, opening up endless possibilities for manufacturing and design. If you're looking for a high-quality 3D printing solution, I highly recommend considering one with sintering capabilities.

I recently purchased a 3D printer with sintering capabilities and I have been blown away by the results. The sintering process allows for high levels of detail and strength in the printed objects, making them perfect for functional prototypes and end-use parts. The precision and accuracy of the sintered prints are unmatched, and the finished products have a smooth surface finish that requires minimal post-processing. The sintering technology has opened up a whole new world of possibilities for my 3D printing projects, and I couldn't be happier with the quality of the prints it produces. I highly recommend considering a 3D printer with sintering capabilities for anyone serious about their 3D printing endeavors.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours