- Home

- Vacuum Injection Molding

Vacuum Injection Molding Manufacturer: high-quality products at wholesale prices

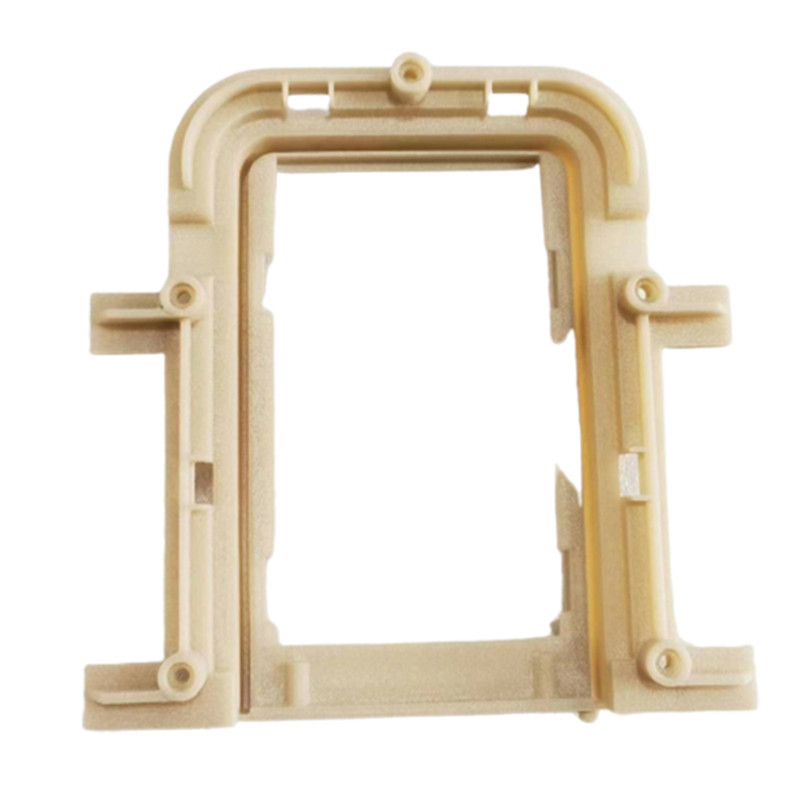

Introducing our cutting-edge vacuum injection molding technology, brought to you by Guangdong Shunde Teamwork Model Co., Ltd. As a leading manufacturer, supplier, and factory in China, we are proud to offer this advanced process for creating high-quality, precision components for a wide range of industries.

Our vacuum injection molding process involves injecting liquid resin into a mold under vacuum pressure, resulting in superior material distribution, reduced porosity, and enhanced mechanical properties. This innovative technique allows for the production of complex and intricately detailed parts with exceptional accuracy and consistency.

With our state-of-the-art facilities and expert team, we are committed to delivering the highest standards of quality and performance in every product we manufacture. Whether you require prototypes, small batches, or large-scale production runs, our vacuum injection molding capabilities can bring your designs to life with unparalleled precision and efficiency. Partner with Guangdong Shunde Teamwork Model Co., Ltd. for all your vacuum injection molding needs.

Guangdong Shunde Teamwork Model Technology Co., Ltd.

Company News

Related News

Fabrication CNC Machining Rapid Prototype ABS Plastic Parts Factory

ABSPlast Factory - Your trusted source for high-quality ABS plastic parts. Specializing in fabrication, CNC machining, and rapid prototype manufacturing.

Custom CNC Machining Brass / Aluminum Prototyping Parts

Precision Prototypes: Custom CNC Machining Brass / Aluminum Parts. Get high-quality prototyping from our factory for your manufacturing needs.

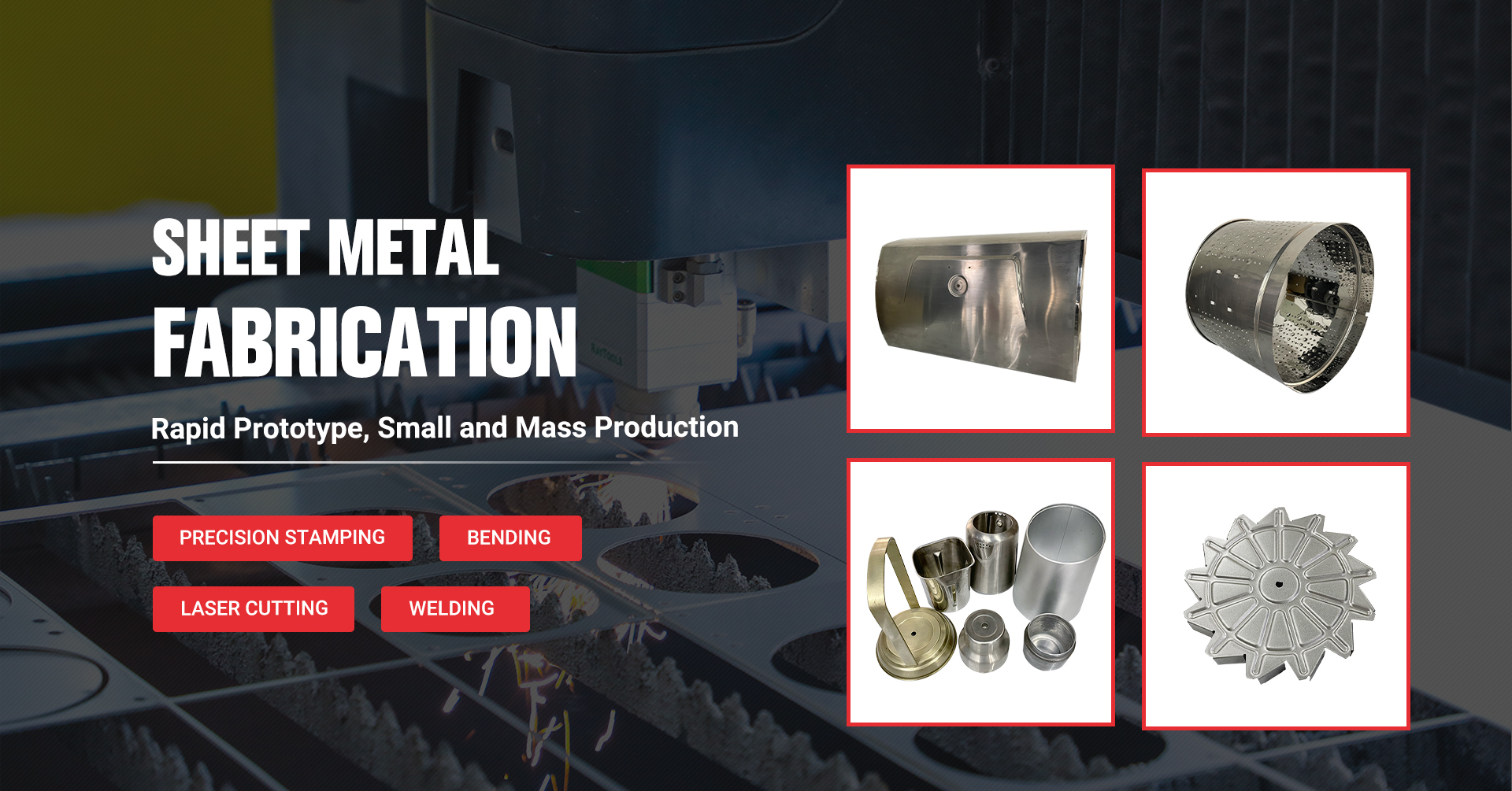

Sheet Metal Fabrication Aluminum Enclosure Laser Cutting Bending Stamping Parts

Aluminum Enclosure Factory: Expert in Sheet Metal Fabrication, Laser Cutting, Bending & Stamping Parts. Get high-quality and precise products at our factory.

Fabrication CNC Machining Rapid Prototype ABS Plastic Parts Factory

Introducing our new product line: ABS Plastic Parts. Precision crafted at our CNC Machining Rapid Prototype Factory for top-quality fabrication.

Custom Black ABS Resin CNC Machining Parts Plastic Prototypes

Discover high-quality custom black ABS resin CNC machining parts plastic prototypes at our factory. We offer precision manufacturing and fast turnaround times.

Custom precision rapid prototype ABS plastic 3D printing parts services

Factory direct custom precision ABS plastic 3D printing parts services. Get rapid prototypes with high-quality and fast turnaround times.

OEM CNC Machining Parts Stainless Steel Turning Miling Parts

Shop stainless steel turning and milling parts from our OEM CNC machining factory. Precision parts for all industries.

Plastic and metal components of medical equipment, appearance prototype

Product name: MediPro Prototype We are a factory specializing in producing appearance prototypes for medical equipment with precision plastic and metal components.

Sheet Metal Fabricator Stamping Parts Laser Cutting Service

Precision Metalworks: Leading manufacturer providing professional Sheet Metal Fabricator, Stamping Parts, and Laser Cutting Service. Quality assured.

Stainless Steel Metal Stamped Parts Sheet Metal Fabrication

Precision MetalWorks: Your go-to source for stainless steel metal stamped parts and sheet metal fabrication. We are a trusted factory with the expertise you need.

Customized precision component metal machining parts CNC aluminium part service

Custom Precision Metal Machining Parts - CNC Aluminium Part Service. We are a factory specializing in providing customized metal machining solutions for precision components.

OEM 3D Printing Rapid prototyping SLA SLS Printing Service Manufacturer in China

China's leading OEM 3D Printing Rapid Prototyping SLA SLS Printing Service Manufacturer. We are a factory specializing in high-quality 3D printing solutions.

High Performance 3D Printing Metal Parts Rapid Prototyping Service

High Performance 3D Printing Metal Parts Rapid Prototyping Service is offered by our factory. Get quick and reliable metal prototypes for your projects.

OEM Chinese 3D Printing SLS PA Nylon Model Sample Prototype Factory

Welcome to our OEM Chinese 3D Printing SLS PA Nylon Model Sample Prototype Factory. As a leading manufacturer, we specialize in producing high-quality 3D printed prototypes.

Custom automotive sheet metal/metal prototype parts

Custom Automotive Metal Works - Quality prototype parts made at our factory. Specializing in sheet metal fabrication for automotive applications.

- Vacuum Injection Molding Manufacturer: High-Quality OEM Services from China

- Reviews

- Related Videos

Introducing our latest innovation in manufacturing technology – Vacuum Injection Molding. This cutting-edge process allows us to create high-quality, precision-molded products with exceptional efficiency and accuracy. By using vacuum pressure to remove air from the mold cavity before the resin is injected, we are able to produce parts with superior surface finish and reduced voids, making it perfect for applications that require high optical clarity and tight tolerances. Our Vacuum Injection Molding process ensures excellent material distribution and a uniform polymer structure, resulting in parts that exhibit exceptional strength, dimensional stability, and resistance to warping and shrinkage. This makes our products ideal for a wide range of industries, including automotive, aerospace, electronics, and medical devices. In addition to delivering superior part quality, our Vacuum Injection Molding process also offers significant cost savings and faster production cycles. With reduced material waste, shorter cycle times, and minimal need for secondary finishing operations, we are able to provide our customers with a competitive edge in the marketplace. At [Company Name], we are committed to pushing the boundaries of manufacturing technology to deliver the best possible products to our customers. With Vacuum Injection Molding, we are able to set new standards for quality, efficiency, and performance in the industry. Contact us today to learn more about how our Vacuum Injection Molding capabilities can benefit your next project.

I recently used a vacuum injection molding product to create some custom plastic parts for a project, and I was extremely impressed with the results. The vacuum injection molding process allowed for precise, high-quality parts to be manufactured with excellent surface finish and dimensional accuracy. The product was easy to use and gave me the flexibility to create complex shapes and tight tolerances. I was also impressed with the speed of the process, as it reduced the cycle time significantly compared to other molding methods. Overall, I highly recommend vacuum injection molding for anyone looking to produce high-quality plastic parts efficiently.

I recently tried a product made with vacuum injection molding and I was really impressed with the quality. The process creates products with excellent surface finish and precise dimensions, making them look and feel top-notch. The strength and durability of the product were also outstanding, thanks to the uniform distribution of materials achieved through vacuum injection molding. I was also pleased with the design flexibility and intricate details that can be achieved with this process. Overall, I highly recommend products made with vacuum injection molding for their high quality and superior performance.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours