- Home

- Vacuum Process Casting

Vacuum Process Casting Manufacturer in China: High-Quality OEM Supplier

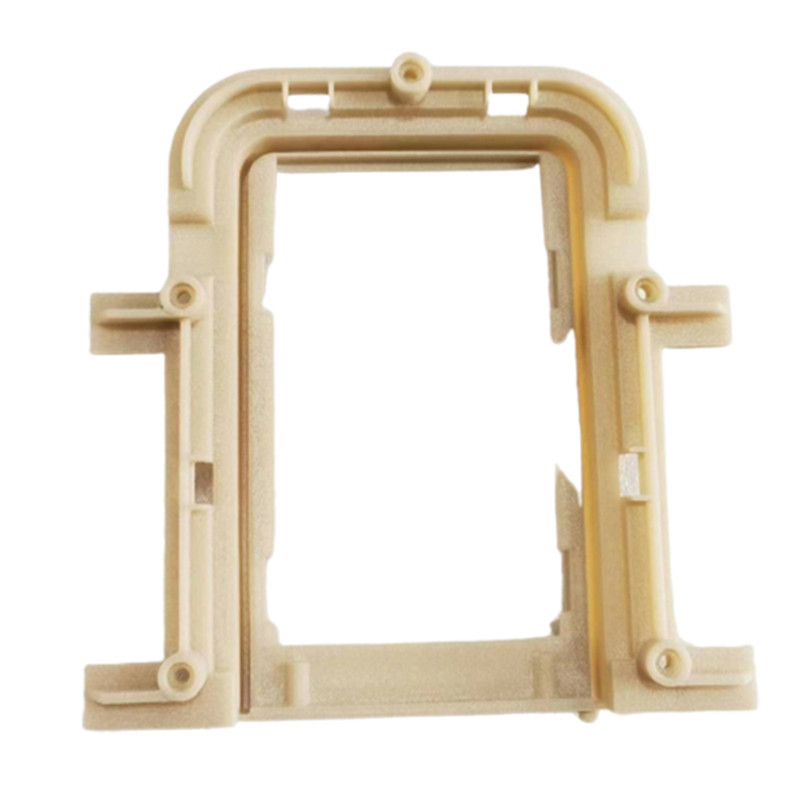

Introducing our latest innovation in casting technology - the Vacuum Process Casting. This advanced method, developed and manufactured by Guangdong Shunde Teamwork Model Co., Ltd., China, revolutionizes the production of high-quality, intricate metal parts.

The Vacuum Process Casting utilizes a vacuum environment to remove unwanted gases from the molten metal, resulting in superior surface finish and mechanical properties. With this cutting-edge technology, manufacturers can achieve precise and complex shapes with minimal porosity and defects, ensuring the highest standard of production quality.

As a leading manufacturer, supplier, and factory of casting equipment, Guangdong Shunde Teamwork Model Co., Ltd. is committed to delivering reliable and efficient solutions for the industry. The Vacuum Process Casting is a testament to our dedication to innovation and excellence in metalworking technology. Experience the difference in quality and performance with our Vacuum Process Casting for your manufacturing needs.

Guangdong Shunde Teamwork Model Technology Co., Ltd.

Company News

Related News

OEM Home Appliance Digital Product CNC 3D Printing Prototype Chinese Factory

Get your OEM home appliance digital product prototype from our Chinese factory. We specialize in CNC and 3D printing to bring your designs to life.

OEM Chinese Customized 3d printed SLA SLS Automotive Prototype Factory

Discover high-quality OEM Chinese Customized 3D Printed SLA SLS Automotive Prototypes at our factory. We specialize in precision and customization.

Custom Precision CNC Machined Aluminum Sandblasting Parts Manufacturing

Get top-quality custom precision CNC machined aluminum sandblasting parts manufactured at our factory. We guarantee high-quality and precise products.

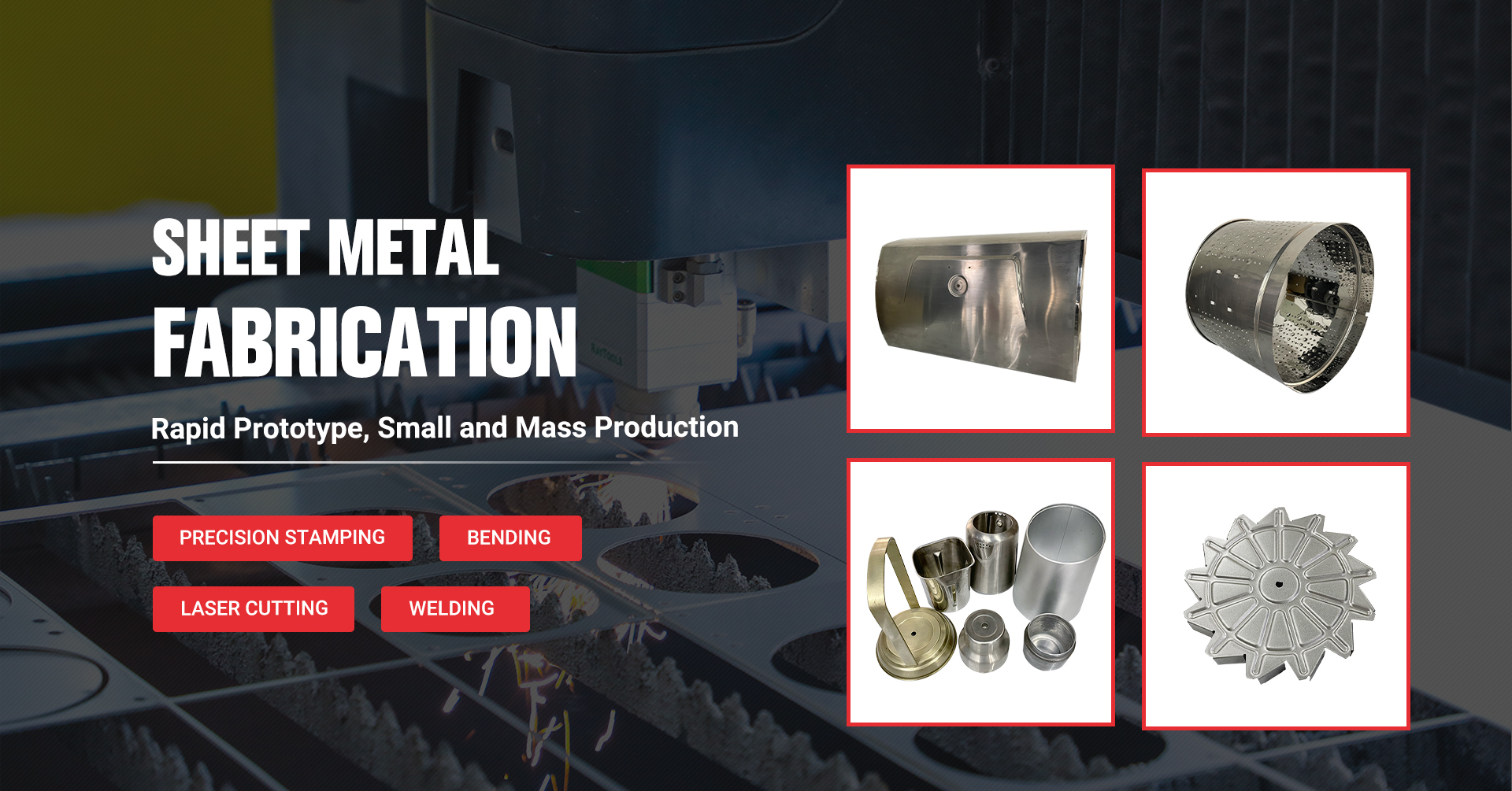

OEM high-quality galvanized steel sheet metal bending service

Introducing "StrongBendz" - Your reliable OEM high-quality galvanized steel sheet metal bending service. We are a trusted factory specializing in precision bending.

Custom CNC Machining Brass / Aluminum Prototyping Parts

Precision CNC Machined Brass and Aluminum Prototypes. Custom-made parts from our factory for rapid prototyping and production runs.

Precision sheet metal laser cutting service manufacturer

Get precise metal cuts with our laser cutting service. As a factory, we deliver high-quality results for all your precision sheet metal needs.

Custom automotive sheet metal/metal prototype parts

MetalCraft ProParts: Your go-to source for custom automotive sheet metal and prototype parts. We are a factory specializing in precision manufacturing.

Custom CNC Machining Brass / Aluminum Prototyping Parts

Precision Prototypes: Custom CNC Machining Brass / Aluminum Parts. Get high-quality prototyping from our factory for your manufacturing needs.

OEM Chinese 3D Printing SLS PA Nylon Model Sample Prototype Factory

Welcome to our OEM Chinese 3D Printing SLS PA Nylon Model Sample Prototype Factory. As a leading manufacturer, we specialize in producing high-quality 3D printed prototypes.

Fabrication CNC Machining Rapid Prototype ABS Plastic Parts Factory

ABSPlast Factory - Your trusted source for high-quality ABS plastic parts. Specializing in fabrication, CNC machining, and rapid prototype manufacturing.

OEM 3D Printing Rapid prototyping SLA SLS Printing Service Manufacturer in China

Explore our range of high-quality OEM 3D printing rapid prototyping SLA SLS printing services. As a leading manufacturer in China, we offer fast and reliable solutions for your prototyping needs.

OEM CNC Machining Parts Stainless Steel Turning Miling Parts

Shop for high-quality OEM CNC Machining Parts Stainless Steel Turning Milling Parts at our factory. Precision manufacturing for your custom needs.

OEM Chinese 3D Printing SLS PA Nylon Model Sample Prototype Factory

Explore our OEM Chinese 3D Printing SLS PA Nylon Model Sample Prototype Factory for high-quality prototypes. We are a leading manufacturer of 3D printed models.

OEM component metal machining parts CNC aluminium factory service

Precision OEM Metal Machining Parts | CNC Aluminium Factory. Get custom machined components with our expert factory service. Contact us today!

High Performance 3D Printing Metal Parts Rapid Prototyping Service

High Performance 3D Printing Metal Parts Rapid Prototyping Service - We are a factory specializing in advanced and speedy metal part prototyping.

- Vacuum Process Casting Manufacturer in China - OEM Supplier of High Quality Casting Products

- Reviews

- Related Videos

Introducing our new and innovative vacuum process casting technology, designed to transform the way metal castings are produced. With our advanced vacuum process casting method, we can create high-quality, complex metal parts with exceptional precision and accuracy. Our vacuum process casting technology utilizes a vacuum to remove air and gases from the mold cavity, ensuring that the molten metal fills the entire mold with ease. This results in castings with superior surface finish and dimensional accuracy, making it perfect for applications where quality and consistency are paramount. One of the key benefits of our vacuum process casting is the ability to produce intricate and delicate parts that traditional casting methods may struggle to achieve. This makes it ideal for industries such as aerospace, automotive, and medical, where complex and lightweight components are often required. Furthermore, our vacuum process casting technology allows for the use of a wide range of metals, including aluminum, titanium, and stainless steel, giving our customers the flexibility to choose the material that best suits their specific needs. Overall, our vacuum process casting technology offers unmatched precision, flexibility, and quality, making it the perfect choice for those looking for top-of-the-line metal castings. Join us in embracing the future of metal casting with our revolutionary vacuum process casting technology.

I recently purchased a product that was made using vacuum process casting and I couldn't be happier with the results. The precision and quality of the finished product is truly outstanding. The vacuum process casting technique has allowed for intricate details and complex shapes to be reproduced with impressive accuracy. The material used is also of high quality, ensuring durability and longevity of the product. I'm impressed with the overall craftsmanship and attention to detail that comes with vacuum process casting. I highly recommend products made using this technique for anyone looking for top-notch quality.

I recently tried a vacuum process casting product and I must say, I was thoroughly impressed. The precision and detail of the final product were exceptional. The casting process was smooth and accurate, resulting in a high-quality finished piece. The vacuum system really made a difference in producing a clean and flawless casting, with minimal porosity and excellent surface finish. Overall, I was very satisfied with the results and would highly recommend vacuum process casting for anyone looking for top-notch quality in their casted products.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours